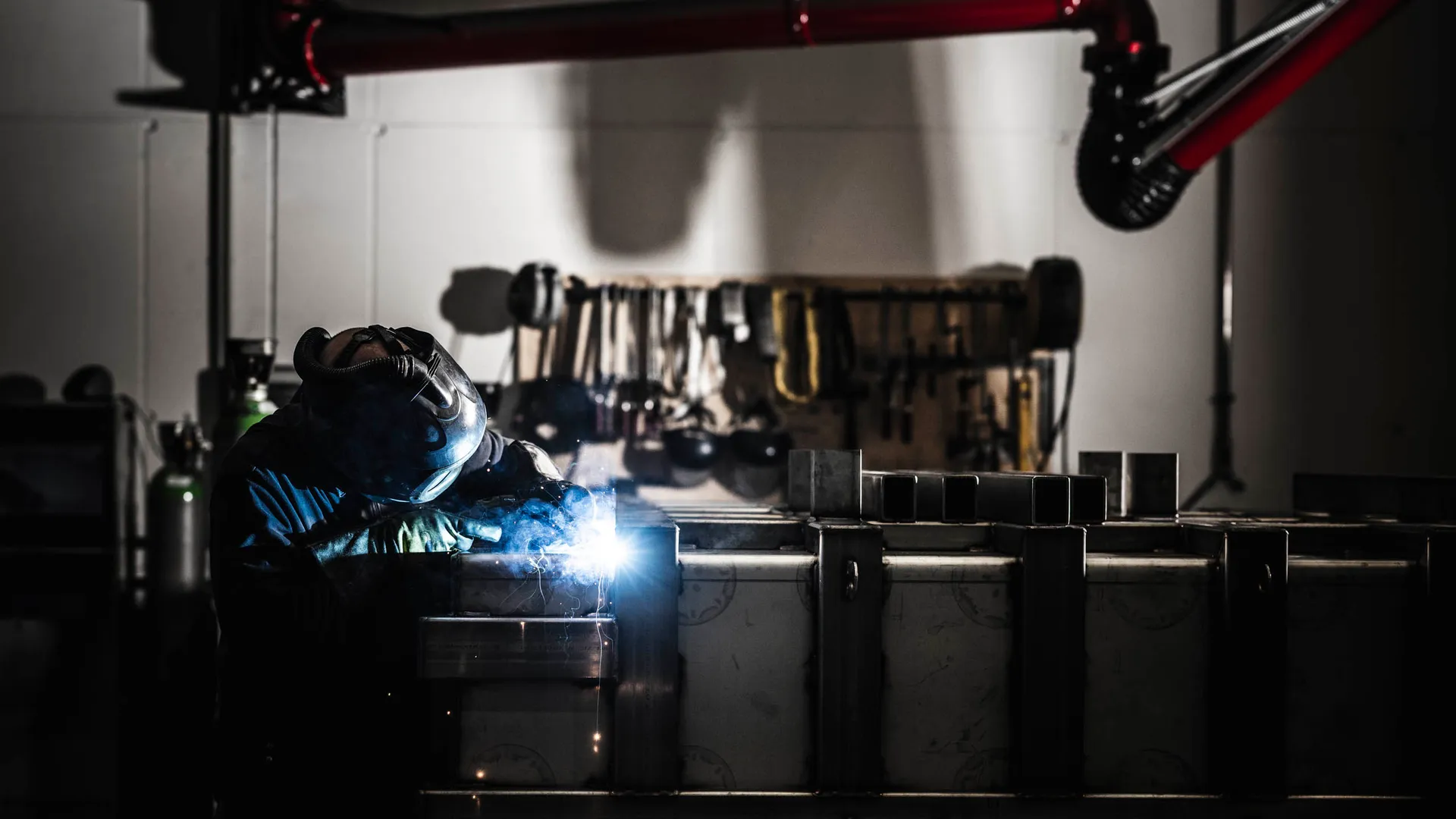

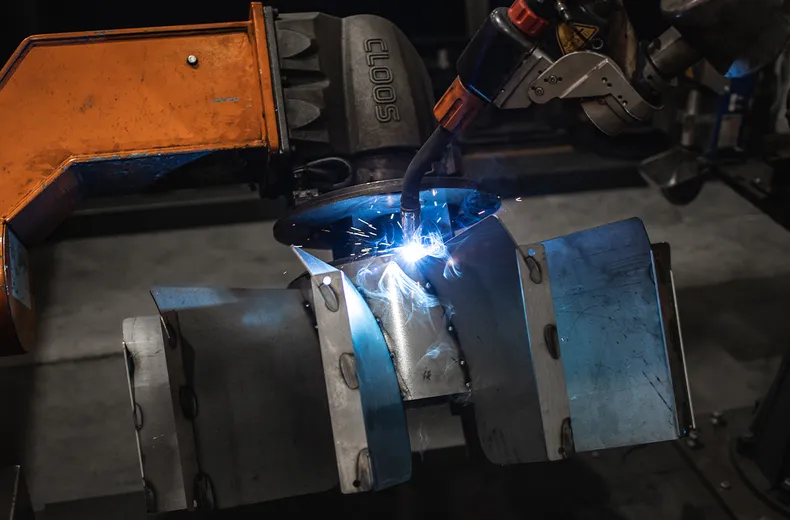

Welding steel, stainless steel & aluminum – precise & certified

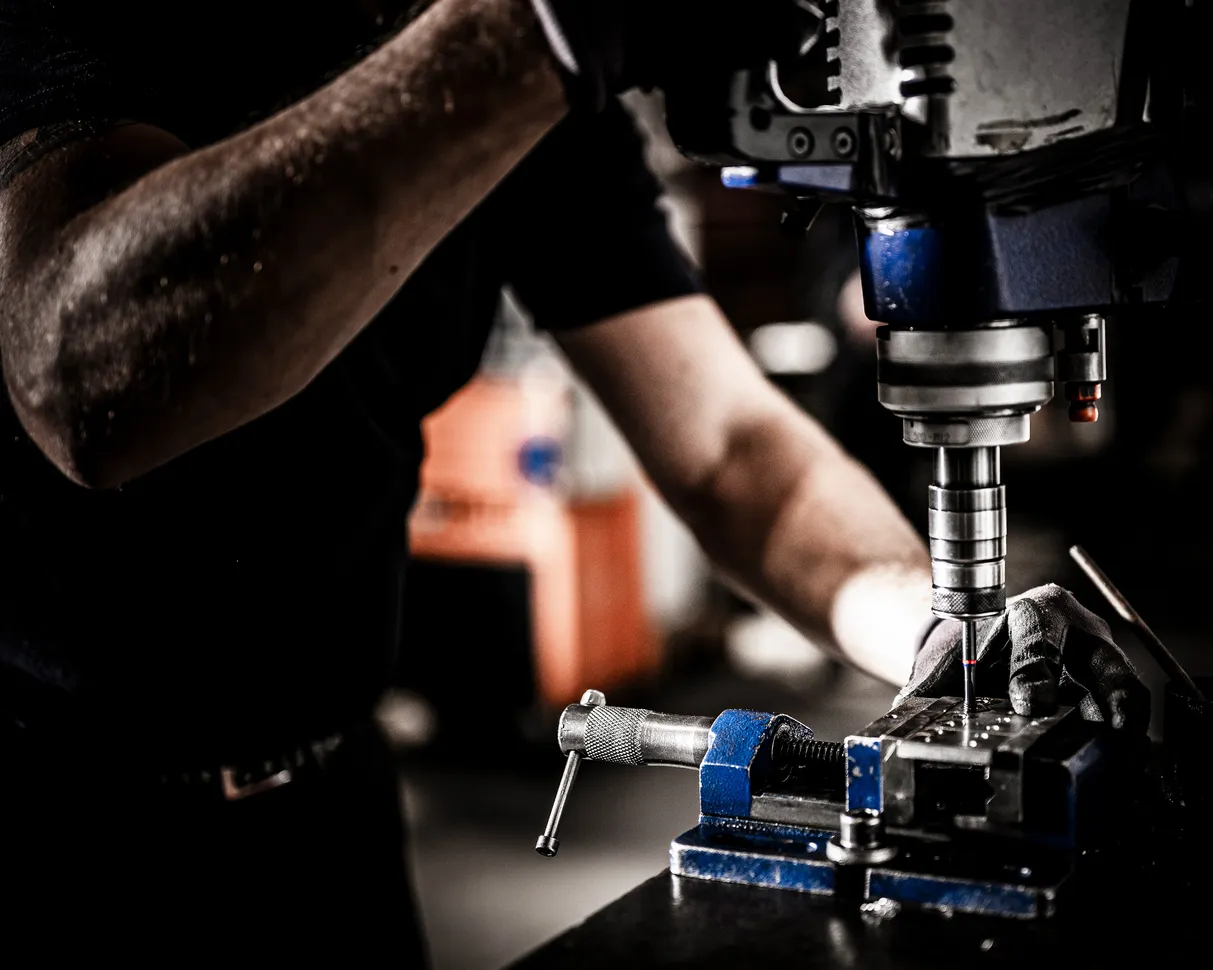

We deliver welding solutions for single parts and series—both manual and automated. Your guarantees: economical, process-safe, and certified to EN 1090. For maximum efficiency, welding can be integrated into full assembly production, including milling, laser marking, surface finishing, and more.