Sheet metal straightening: reliable and process-safe

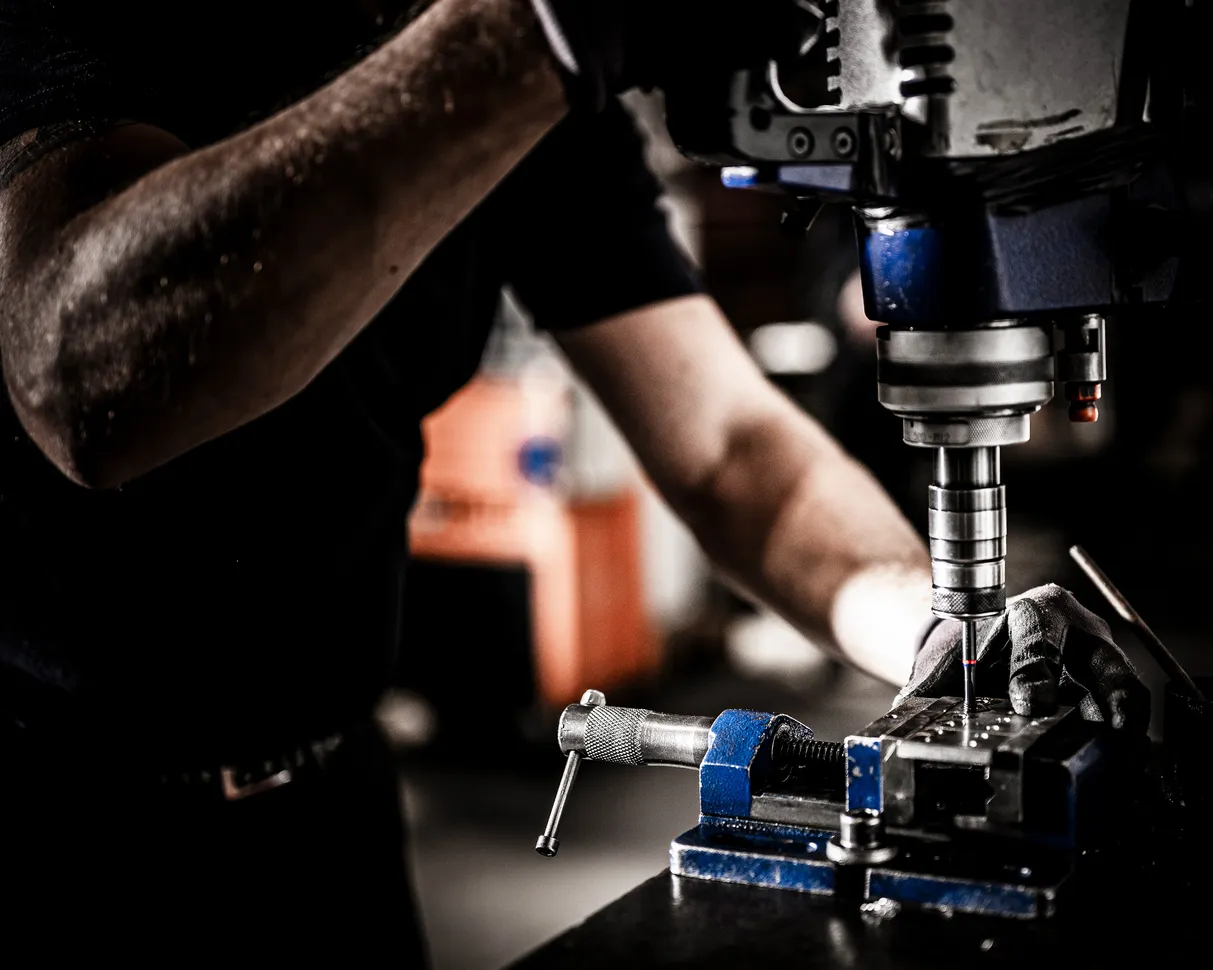

Using state-of-the-art straightening technology, WF Mechanik delivers flat, stress-free sheets—creating the ideal foundation for downstream processing, including automated workflows.

Perfect for tight tolerances and functional parts with demanding dimensional requirements. Beyond advanced machinery, our customers benefit from high vertical integration and quality assurance that’s built in from the start.