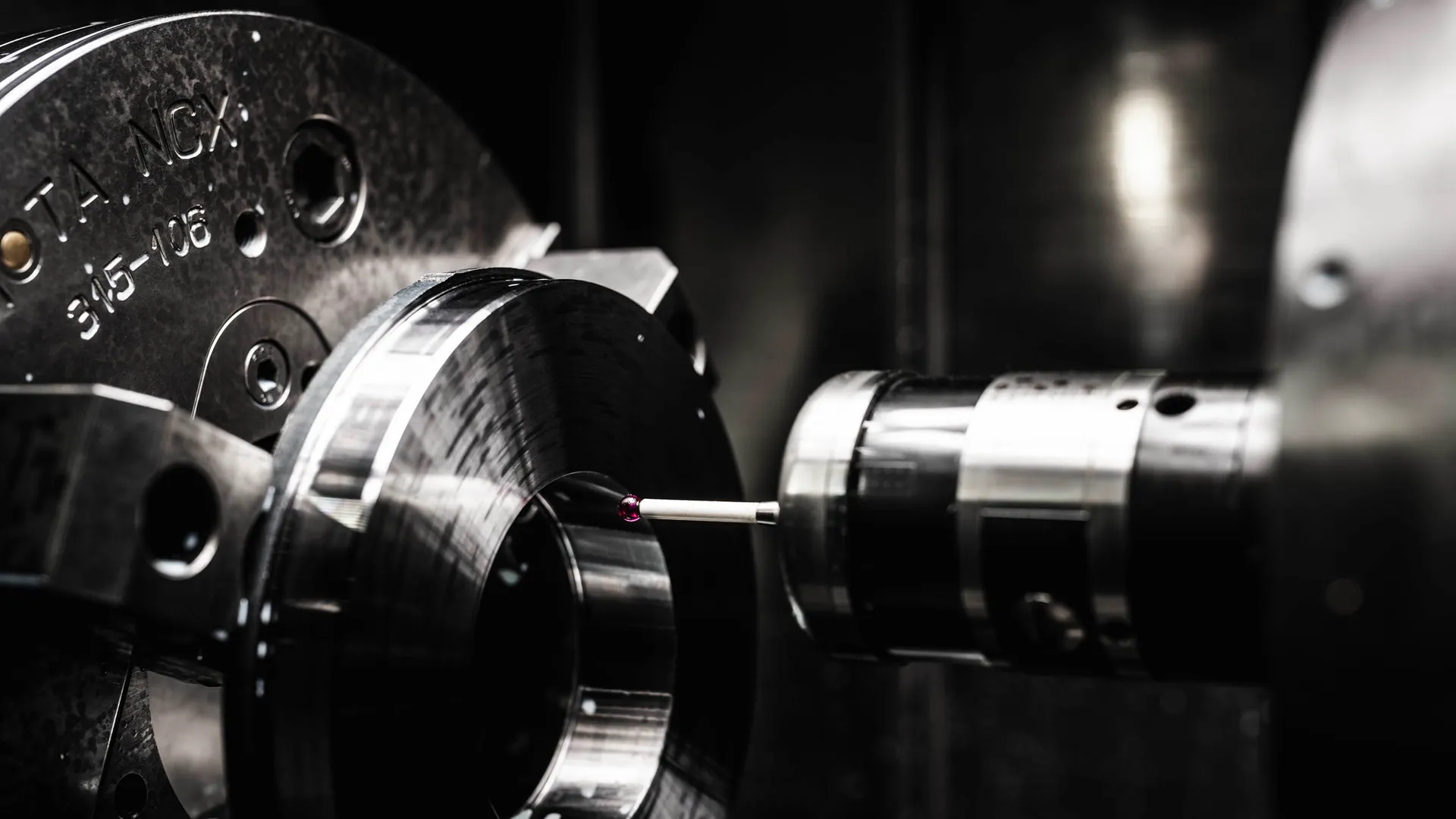

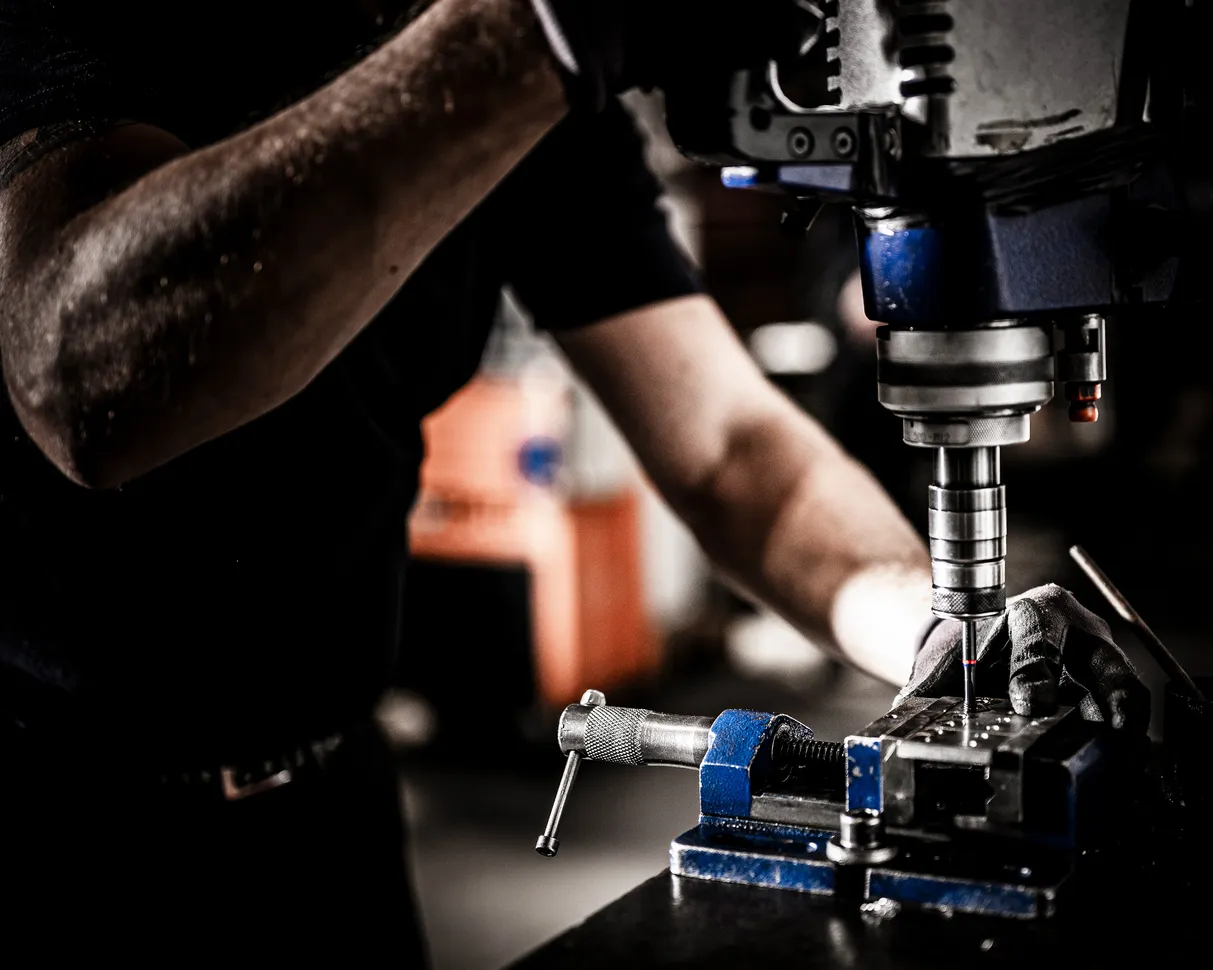

Gears & splined shafts for frictionless torque

As an experienced gear manufacturer, WF Mechanik is a sought-after supplier to the mechanical and automotive sectors.

We produce spur and helical gears as well as keyed shafts and profiled internal gears—precisely, efficiently, and exactly to customer specifications. Production covers prototypes, specials, and series runs. Tight tolerances, accurate flank geometry, and stable fits ensure long-lasting, low-friction power transmission.