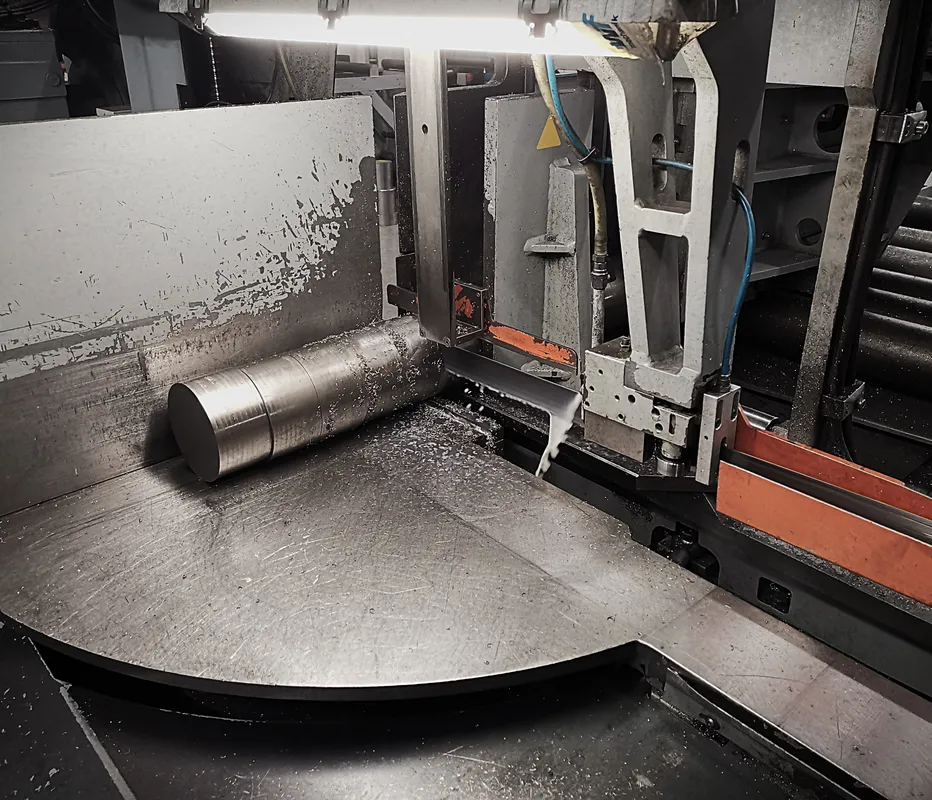

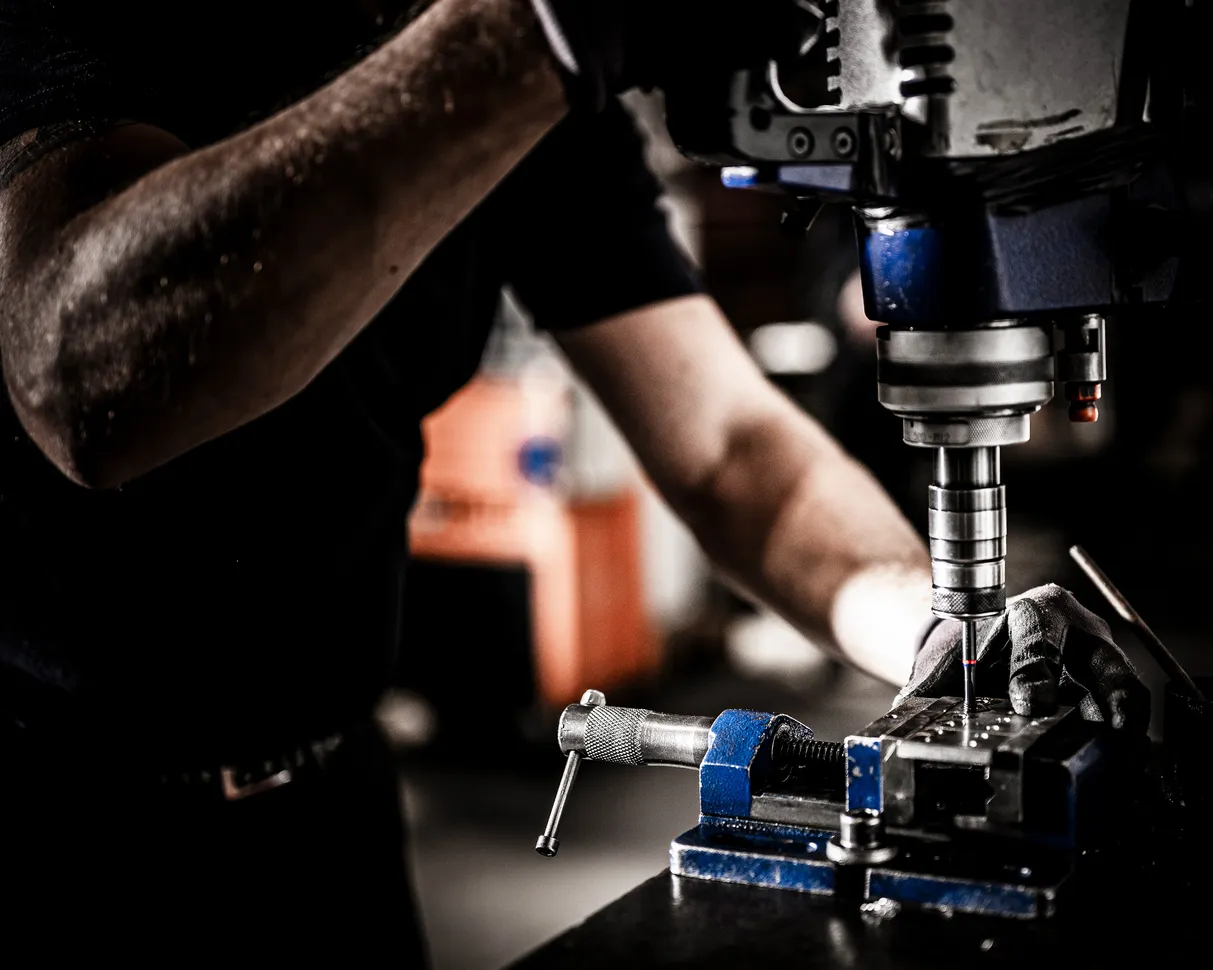

Sawing for accurate raw parts and efficient workflows

Precise cutting of round and solid stock is often the first link in the chain. With modern sawing technology and automated control, WF Mechanik prepares parts to exact size—time-saving, material-efficient, and reproducible. Ideal for seamless handoff to downstream CNC machining.