Satin finishing – metallic surfaces with character

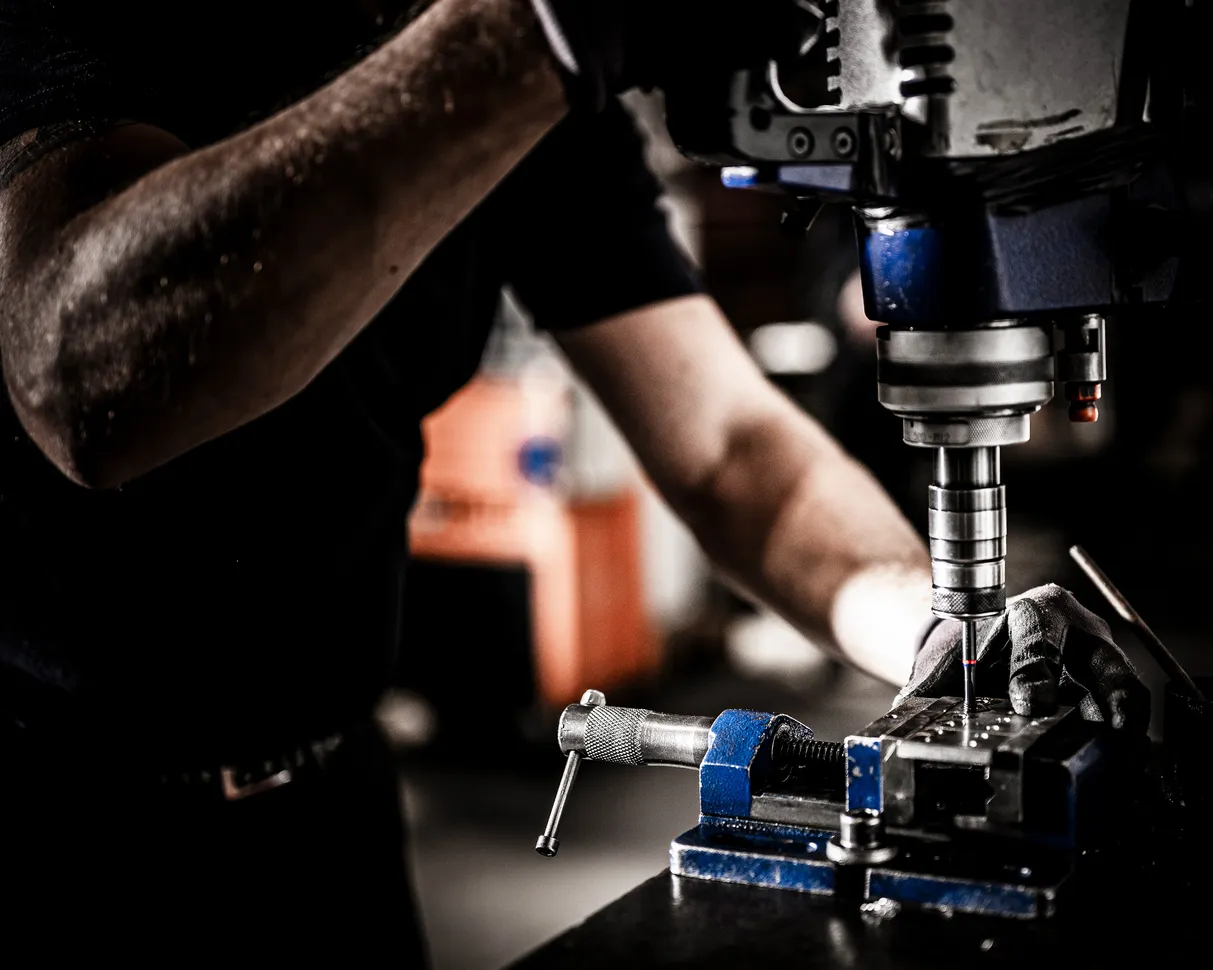

Brushed, satin-matte, or velvety textured: satin finishes are more than aesthetic—they signal quality, precision, and design. With targeted satin-finishing processes, WF Mechanik gives stainless steel, aluminum, copper, and brass a homogeneous, decorative finish with uniform grain and a pleasant feel—without changing the workpiece geometry.