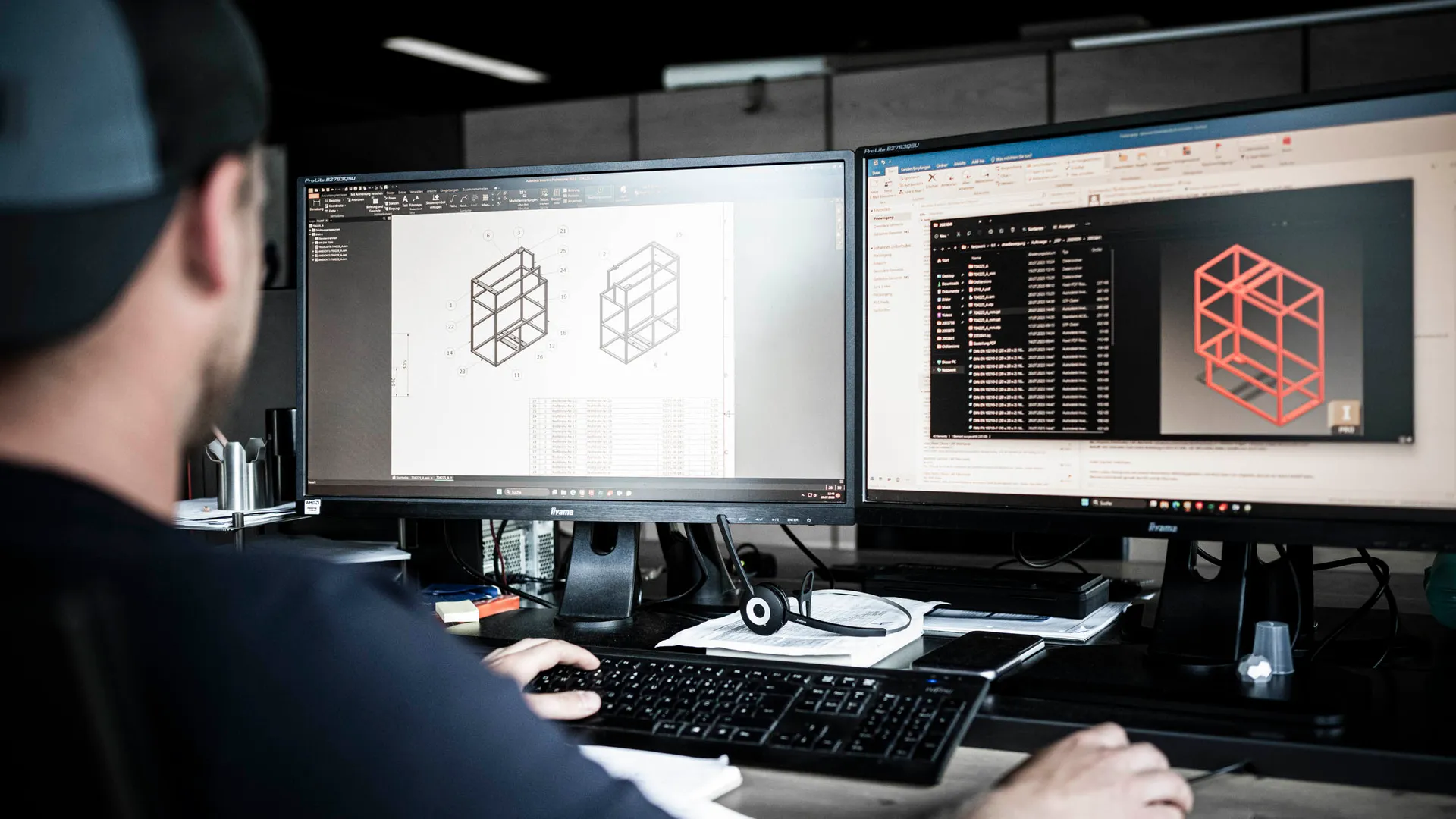

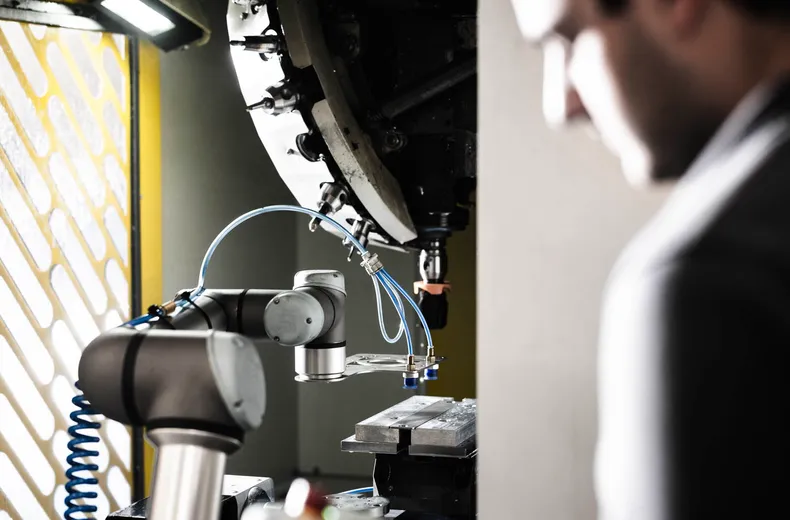

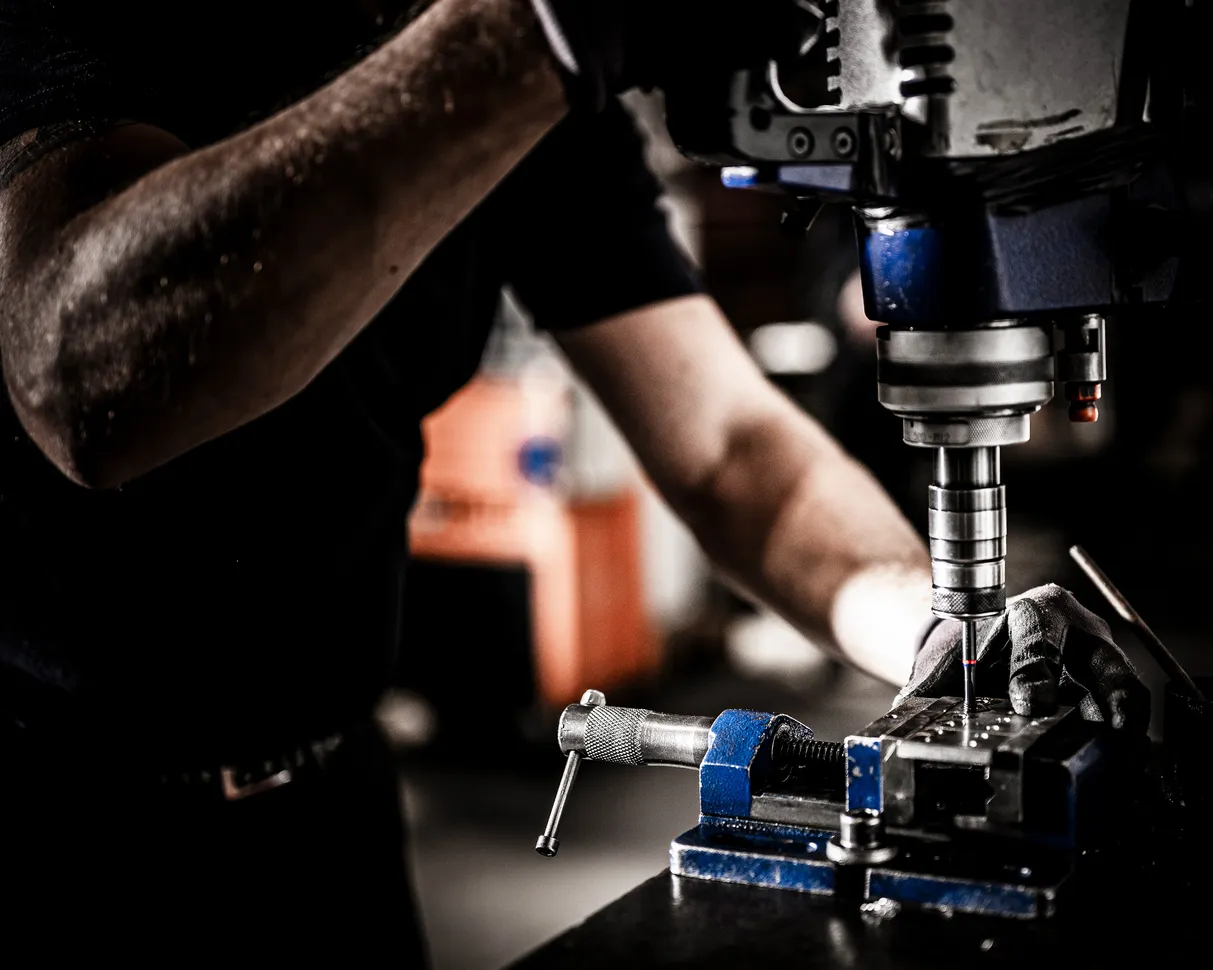

Rapid prototyping – confidence behind every investment

Rapid prototyping is one of the most important steps in product development. Using the optimal method for each project, we quickly and cost-effectively create a prototype of your component. If something doesn’t fit, it becomes clear at this stage—so the design can be refined before final production.