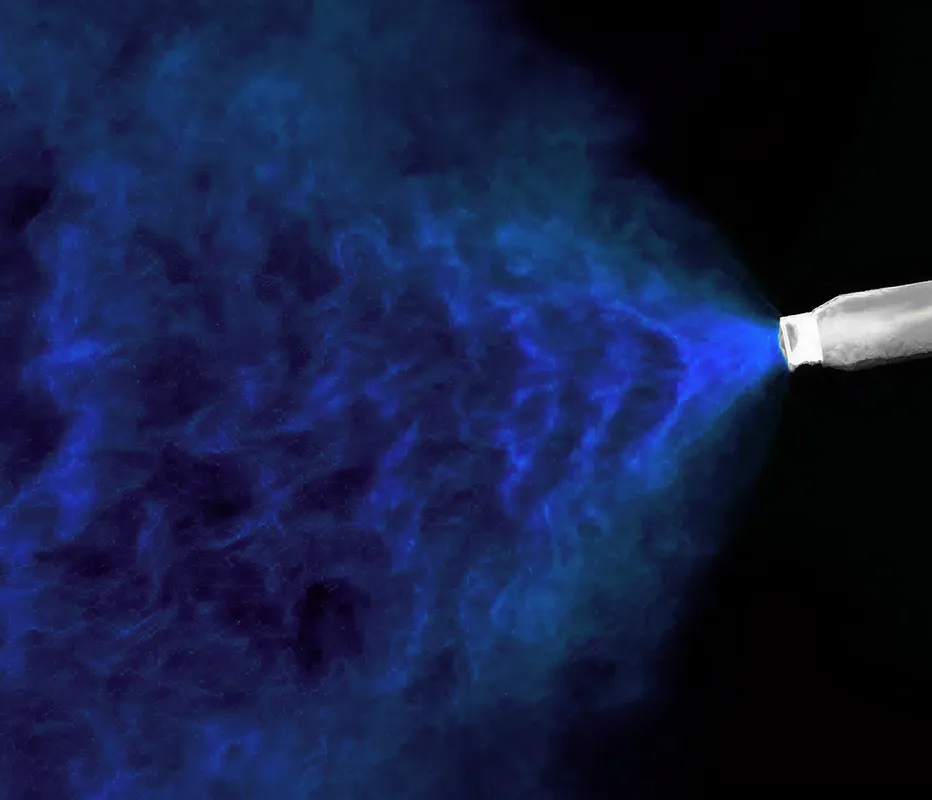

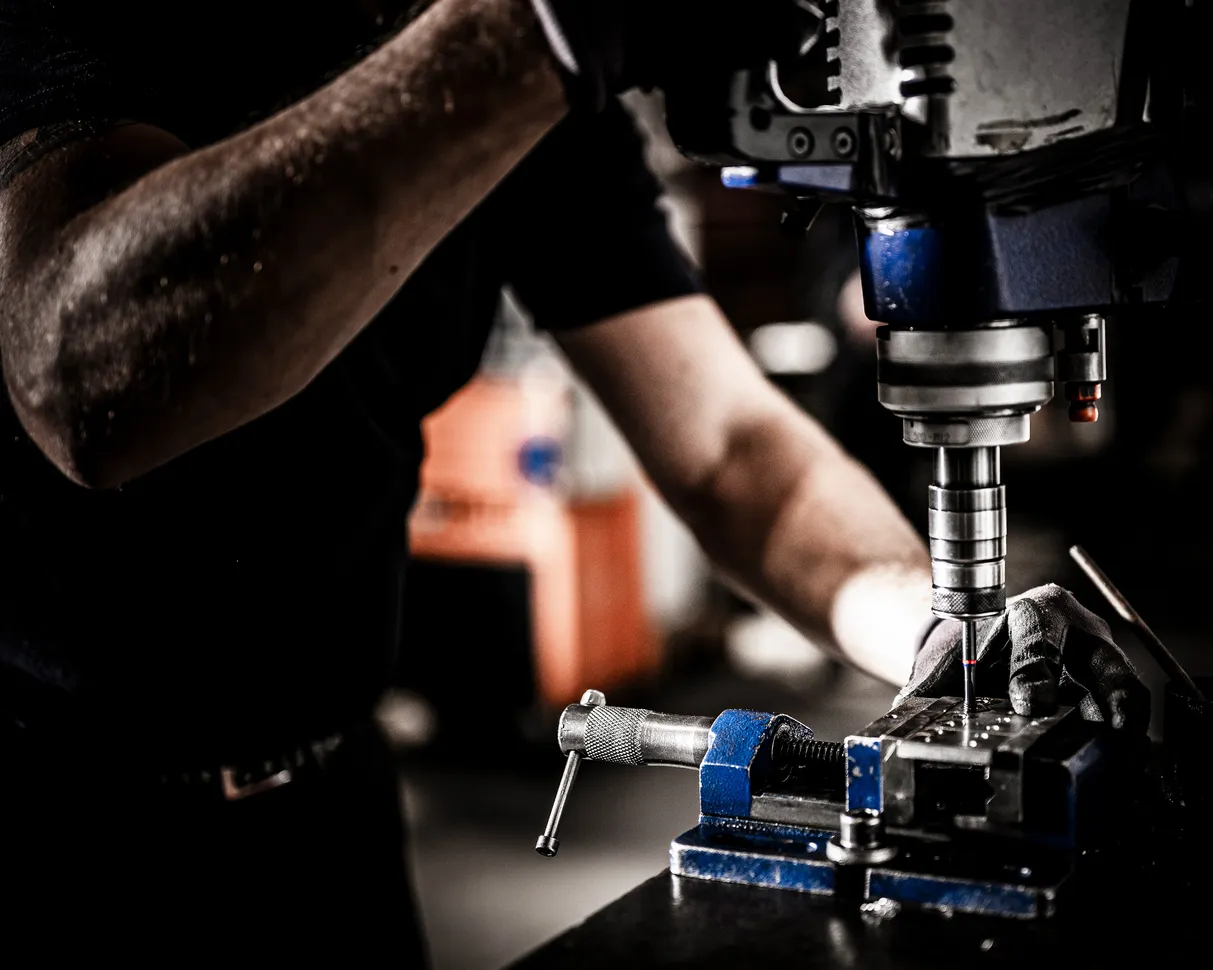

Powder coating of metals – durable, robust, customized

WF Mechanik provides professional powder coating as an integrated finishing step for parts requiring lasting protection and a compelling look. From aluminum profiles and stainless housings to chrome-plated parts—we deliver tough, uniform surfaces with the right color, texture, and protection for every application.