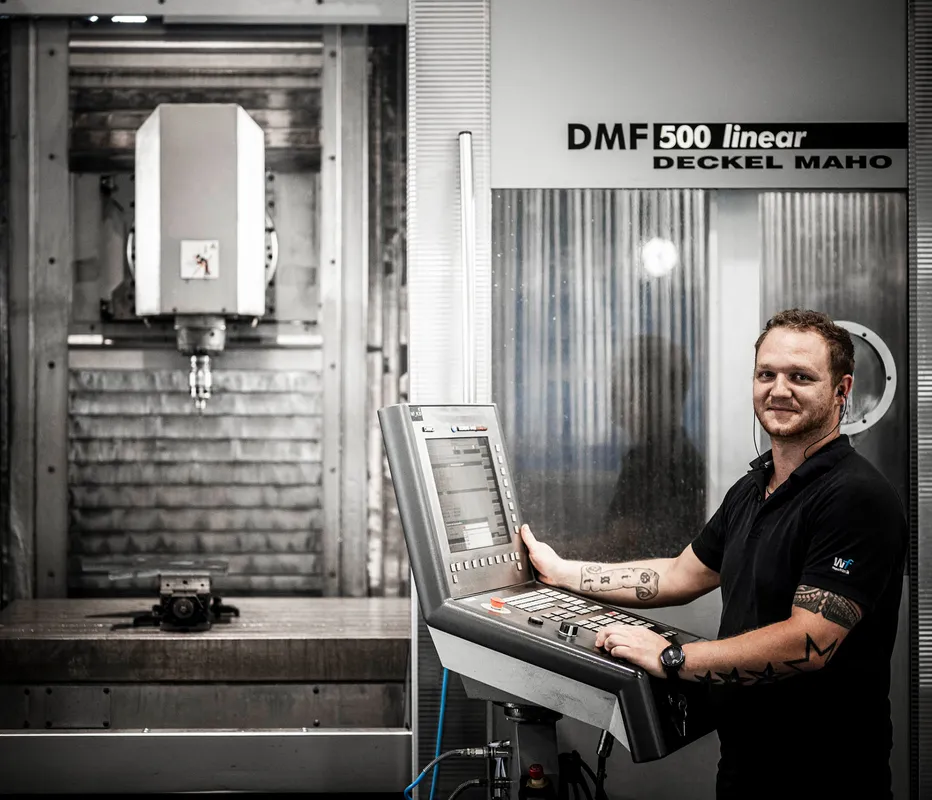

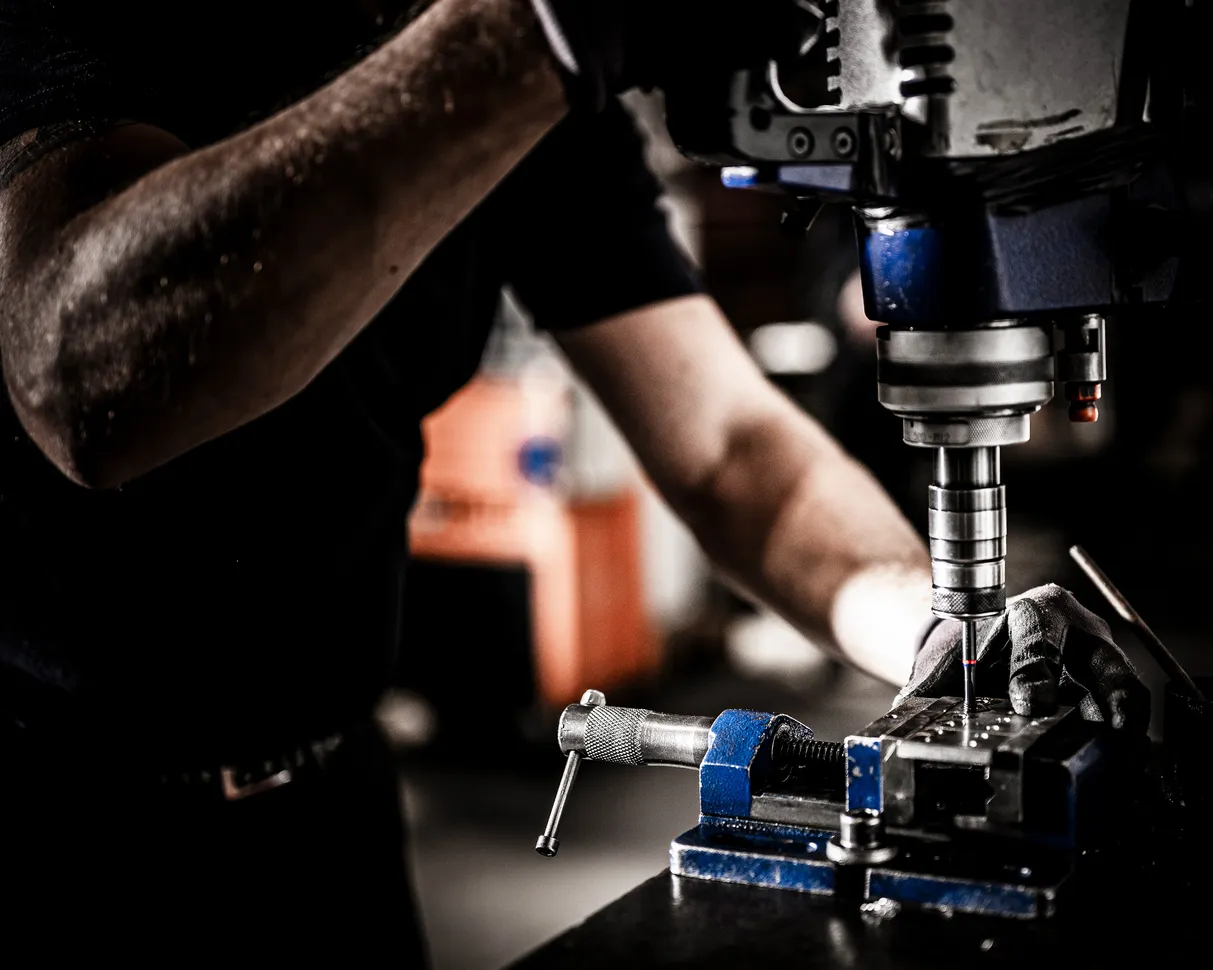

CNC milling for complex contours and premium surfaces

WF Mechanik provides CNC milling for highly complex components in a wide range of materials—including steel, stainless steel, and aluminum alloys as well as engineering plastics such as POM, PTFE, or PEEK. Powerful 5-axis machining centers with linear drives produce sophisticated contours, freeform surfaces, and geometries with outstanding precision.