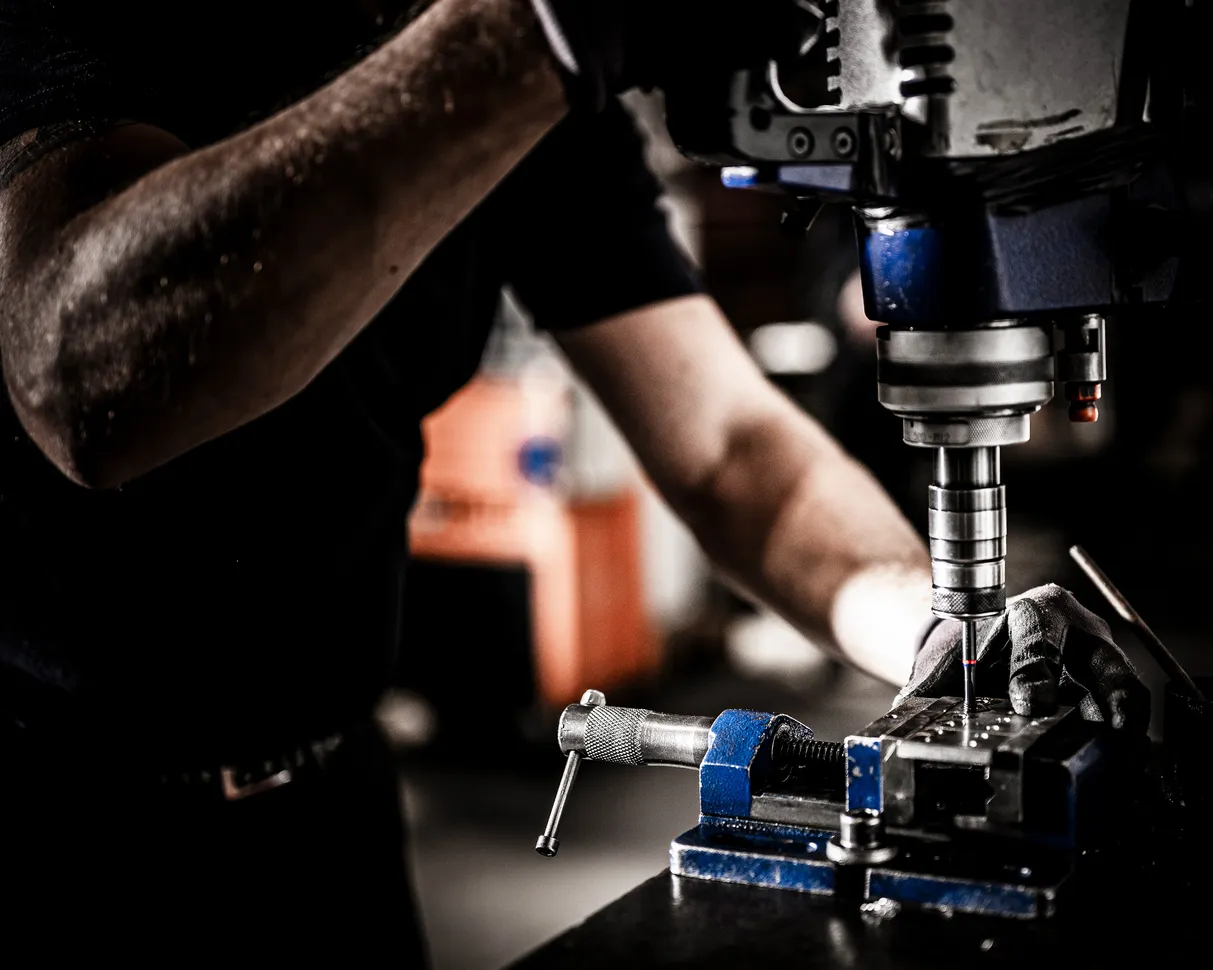

Laser marking – flexible, durable, precise

Whether metal, plastic, or organic materials—we mark and engrave components of all kinds with cutting-edge laser technology. Thanks to flexible systems, even curved, textured, or heat-sensitive surfaces are possible.