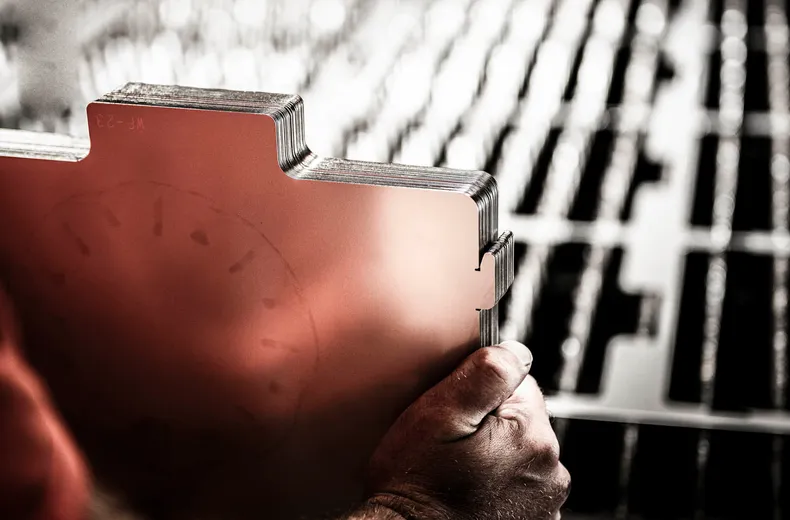

Laser cutting of metals

Laser cutting is one of the most effective methods for separating metals and other materials. Thanks to our flexible laser systems, we process both sheets and tubes—for components with exact, clean contours.

Laser cutting is one of the most effective methods for separating metals and other materials. Thanks to our flexible laser systems, we process both sheets and tubes—for components with exact, clean contours.

01:01

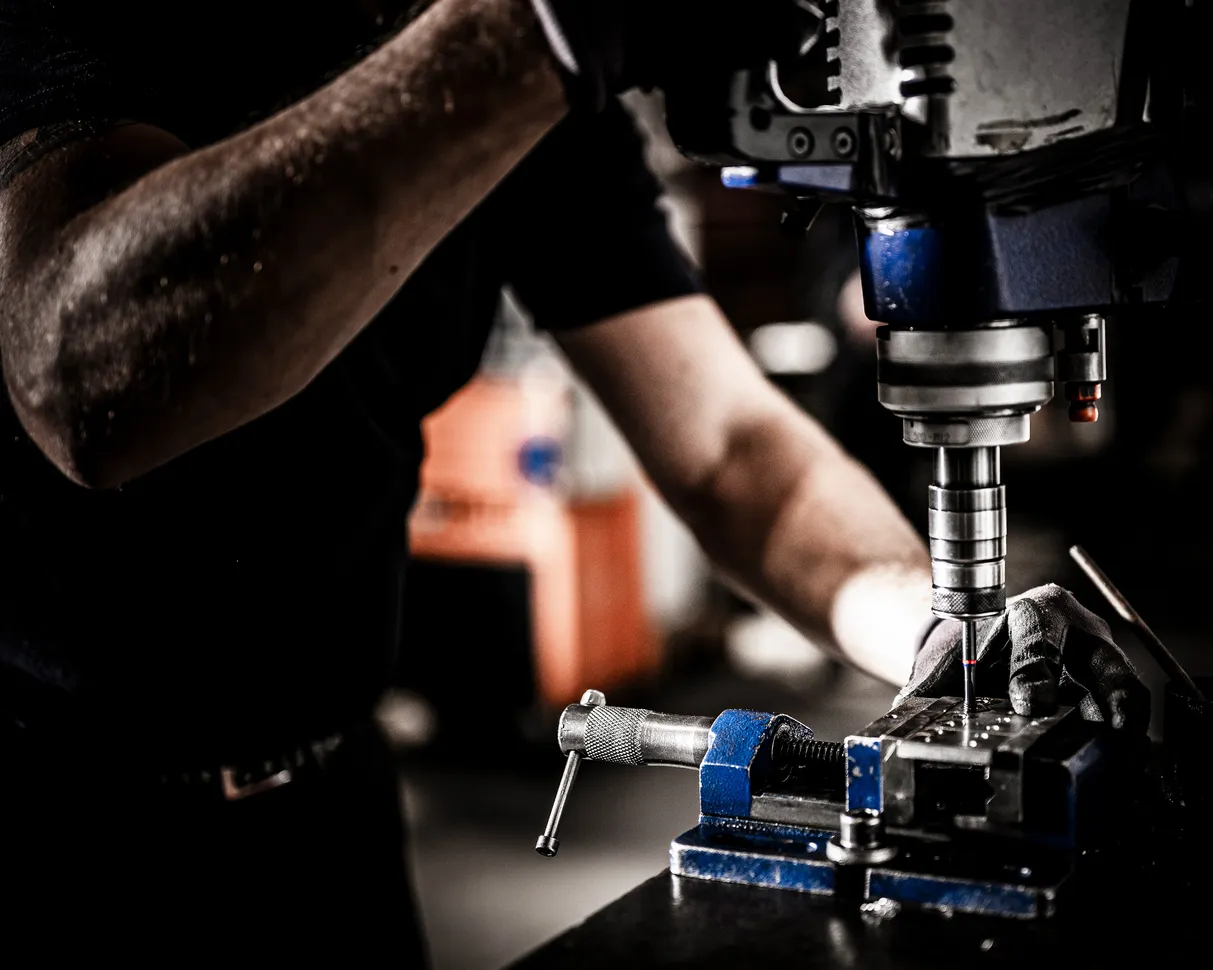

Depending on requirements, we deploy fiber or CO₂ lasers—for top cutting speeds and precision on metals, and optimal cutting of steel or organic materials.

Fiber lasers generate the beam via optical fiber—ideal for thin to medium sheet thicknesses and ultra-fine contours.

CO₂ lasers use a gas mixture and cut plastics and paper as well as wood with high accuracy.

01:02

We produce laser parts to your specifications (hand sketch, CAD data, sample) within a few working days, depending on material availability. For single parts and series, material traceability, part marking, and post-processing—e.g., oxide-free cut edges—are available.

Cutting range max. 4,000 × 2,000 mm,

8 kW resonator

Steel: 25 mm

Stainless steel: 30 mm

Aluminum: 30 mm

Copper: 15 mm

Brass: 12 mm

Wood: 20 mm

315 or 240 mm

3,800 or 6,500 mm

±0.05 mm

dxf, dwg, stp

01:03

With our online tool, you can configure laser parts quickly and conveniently in your browser. Simply upload the DXF file, select material and quantity—and receive an instant, customized quote within seconds. Ideal for prototypes, spare parts, and series production.

Your benefits:

All our manufacturing methods are part of an integrated contract manufacturing offer. WF Mechanik customers benefit from short response times, high flexibility, and the ability to calculate, configure, and order sheet metal parts online. Both products and services come directly from us — everything from a single source.

All components are tested using ISO 9001-certified measurement processes, ensuring dimensional accuracy and process stability — especially for safety-critical or assembly-relevant components in mechanical engineering, medical technology, and plant construction.