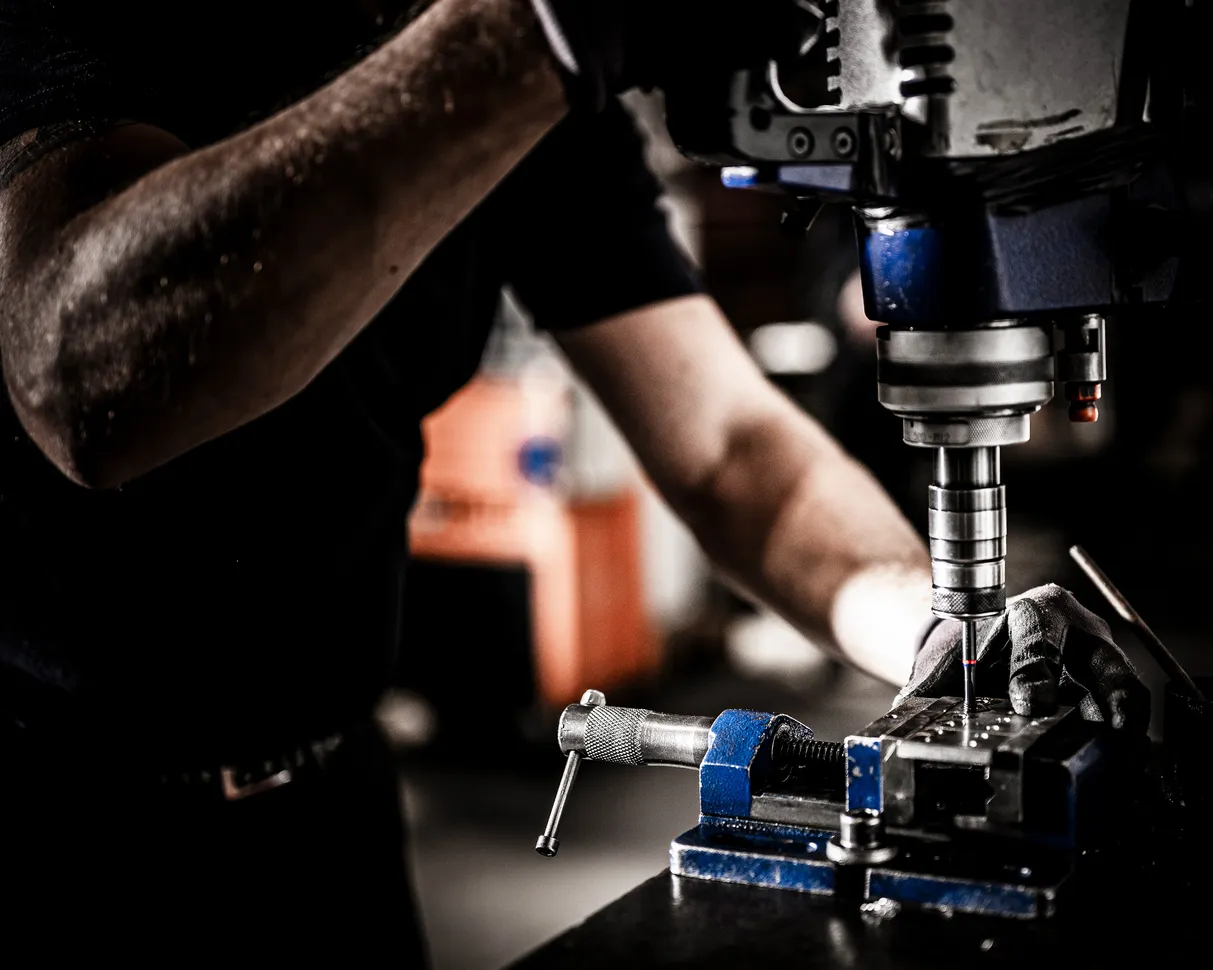

Process reliability & documentation – certified to iso 9001

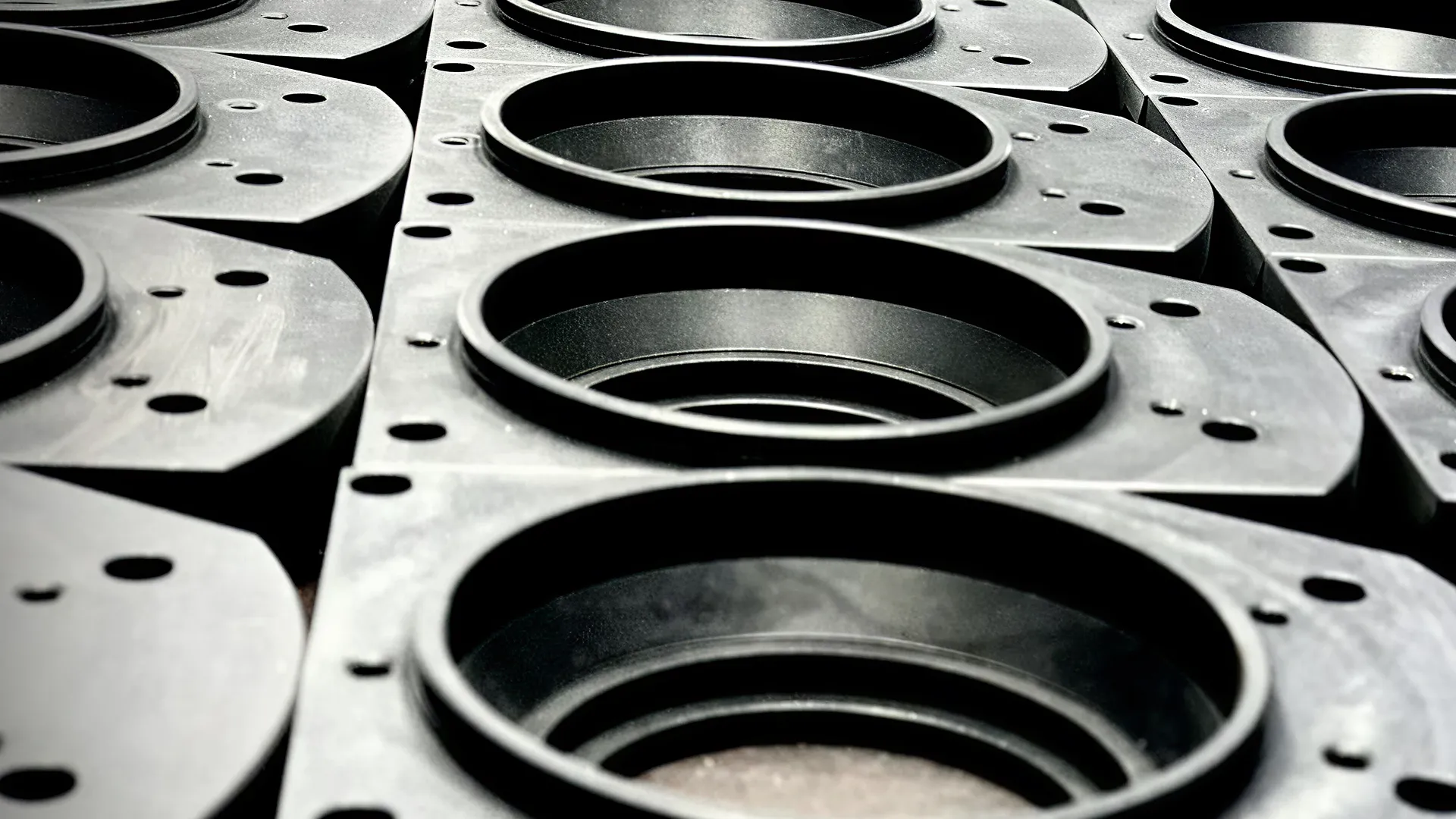

All components are tested using ISO 9001-certified measurement processes, ensuring dimensional accuracy and process stability — especially for safety-critical or assembly-relevant components in mechanical engineering, medical technology, and plant construction.