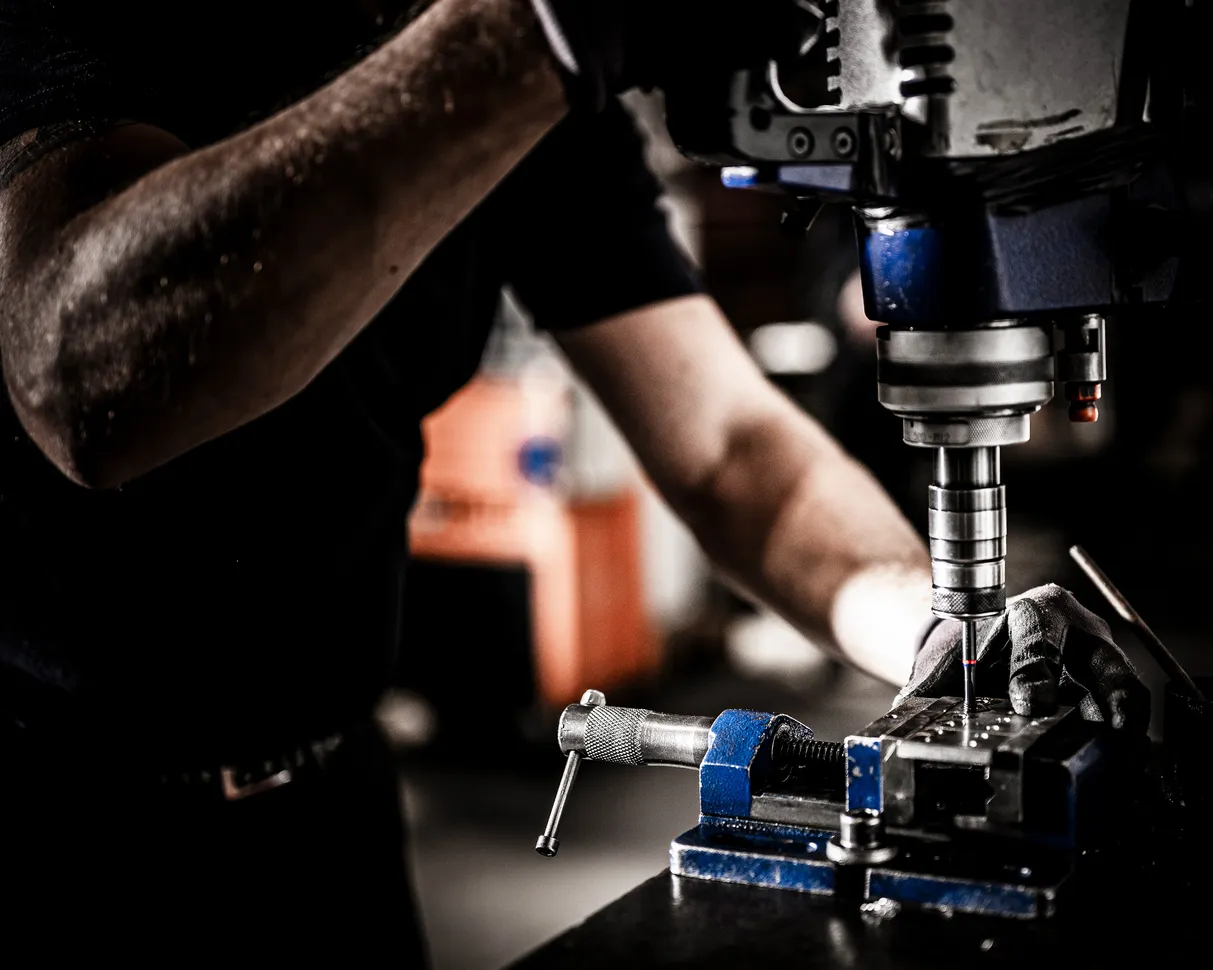

Metal grinding – precision in the micron range

Grinding is essential when tight tolerances, fine surfaces, or perfect geometries are required. Whether preparing for coatings or finishing mating surfaces—we bring metal parts into shape. Cylindrical or surface, manual or CNC-controlled—always with top standards for dimensional accuracy, parallelism, and surface quality.