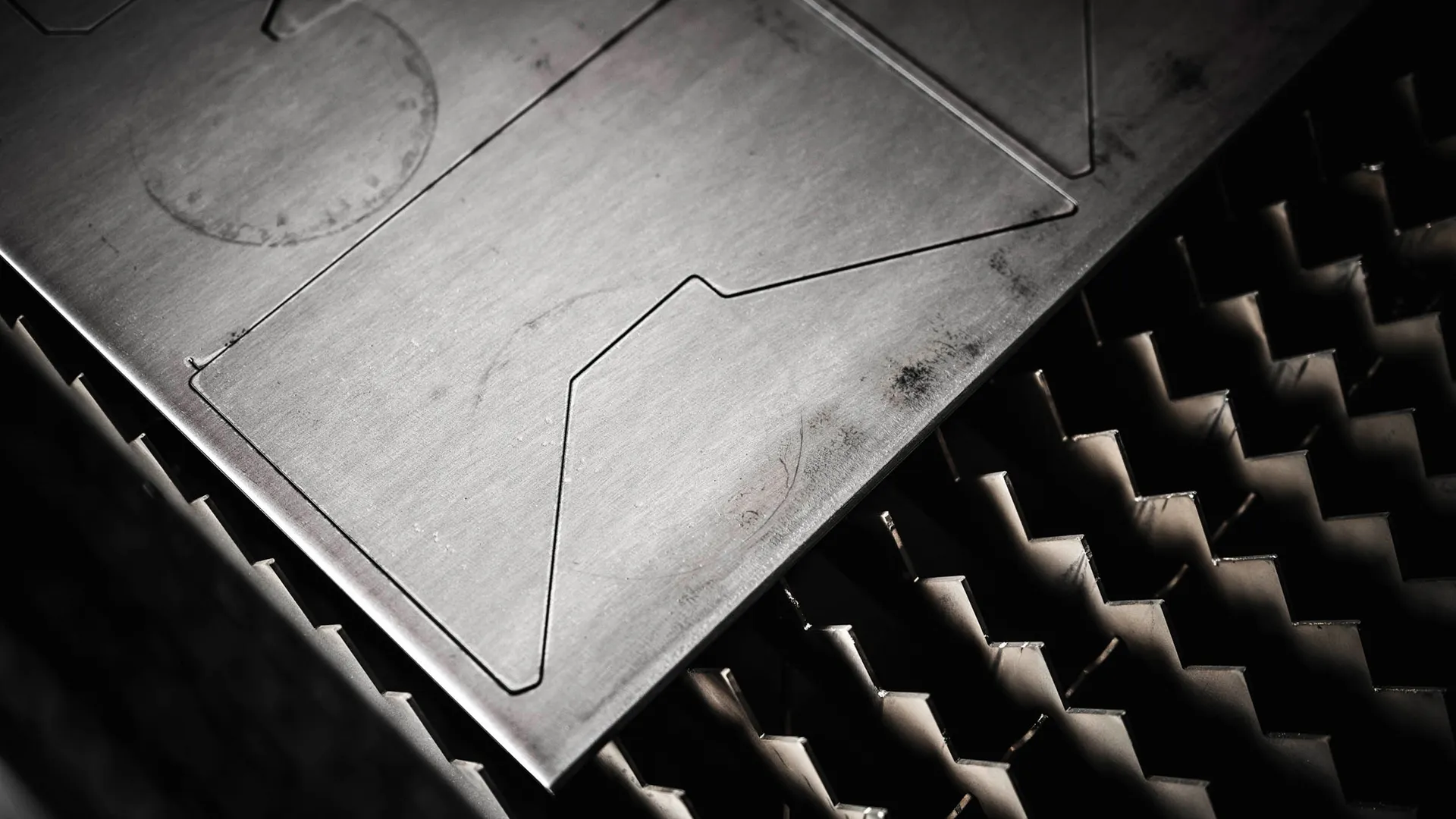

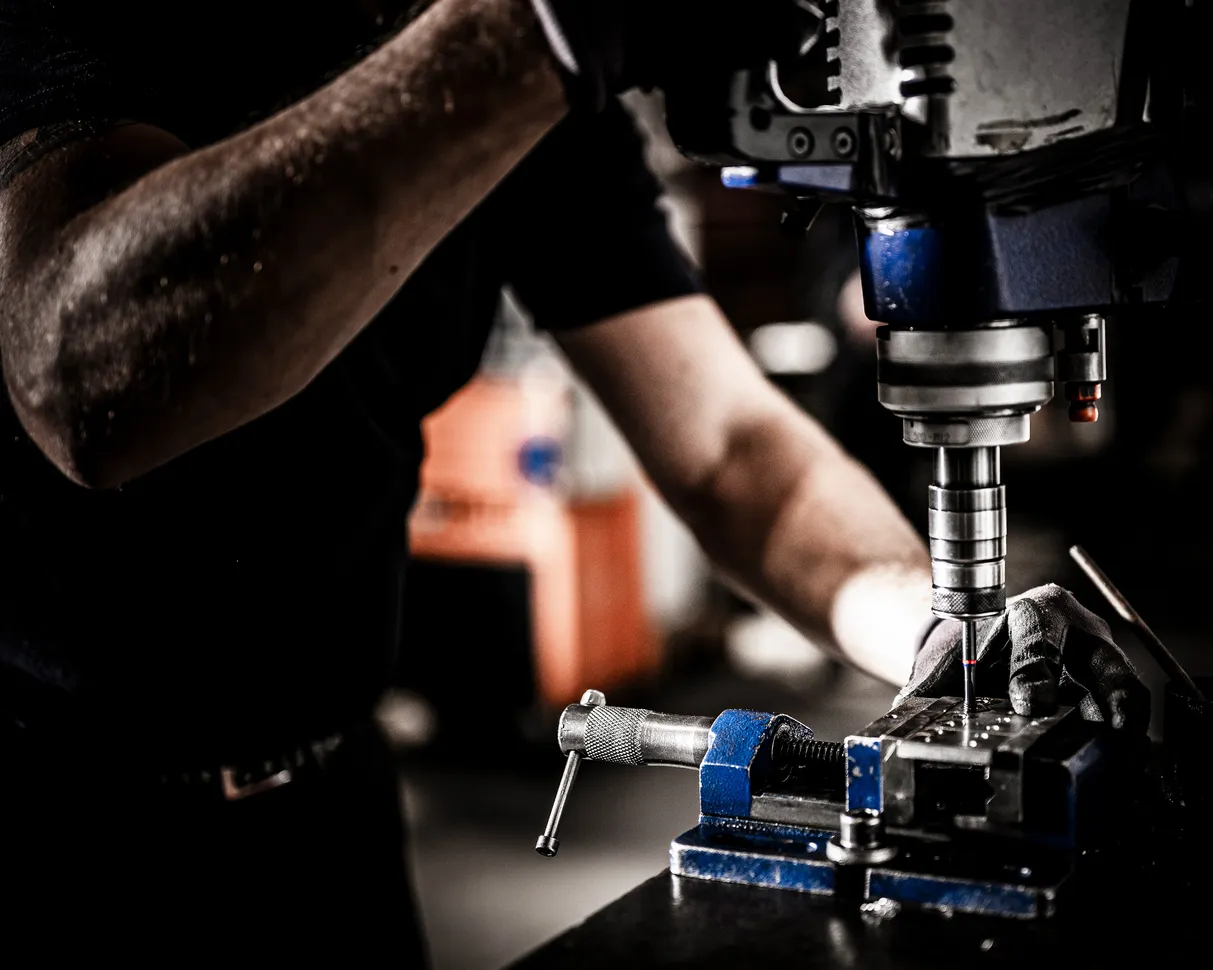

Metal cutting – the foundation of precision manufacturing

From single parts to series production, cutting is the first step toward accurate downstream processing. Whether steel, stainless steel, or aluminum—we cut sheets, tubes, and profiles exactly to size. Depending on material and requirements, we use manual, machine-based, or automated methods.