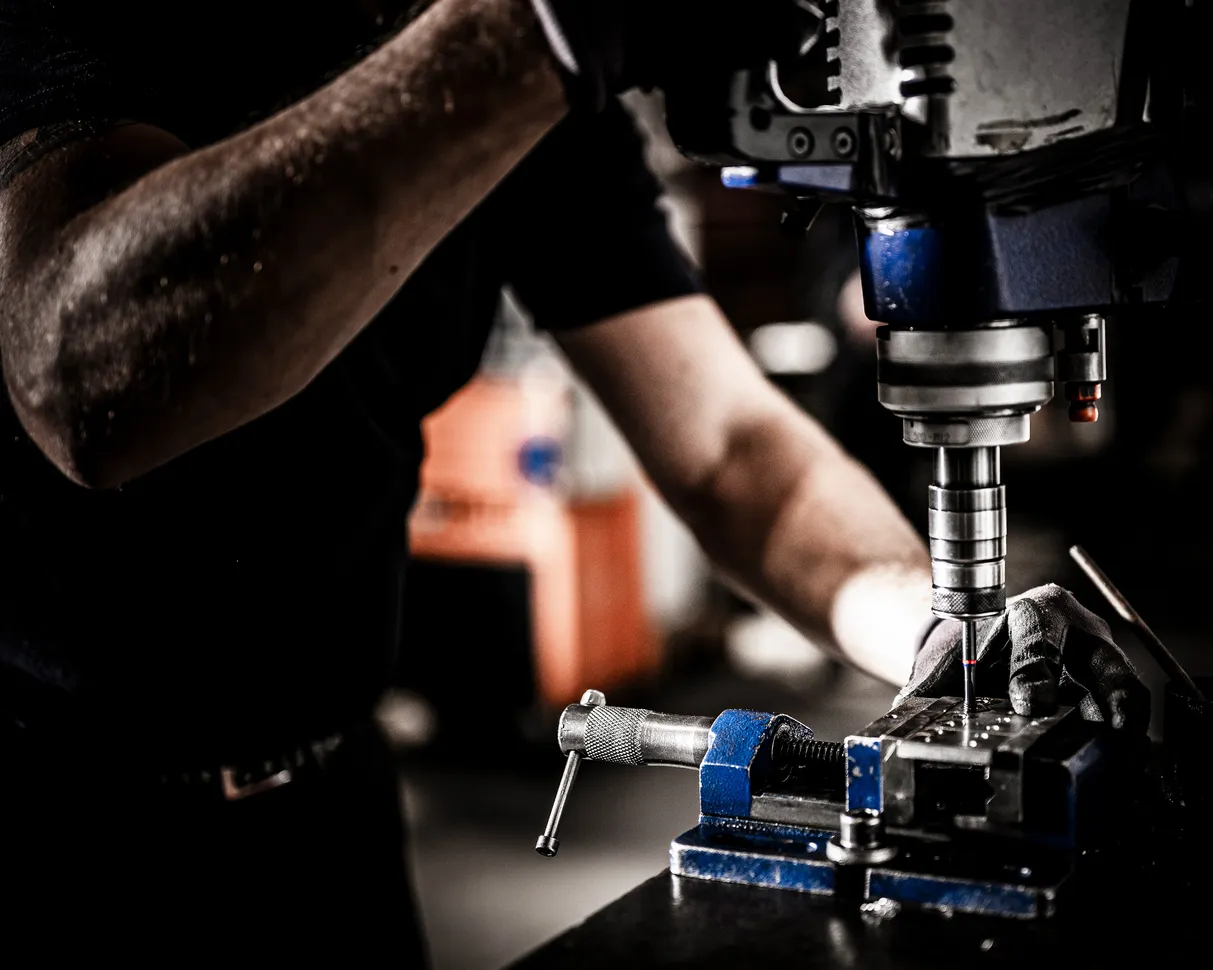

Brushing metal – clean edges, premium surfaces

Brushing precisely mattes, textures, and deburrs metal surfaces. WF Mechanik uses the process to round edges, remove burrs, and create decorative brush patterns—machine or manual. Low removal ensures dimensional accuracy and geometry are preserved.