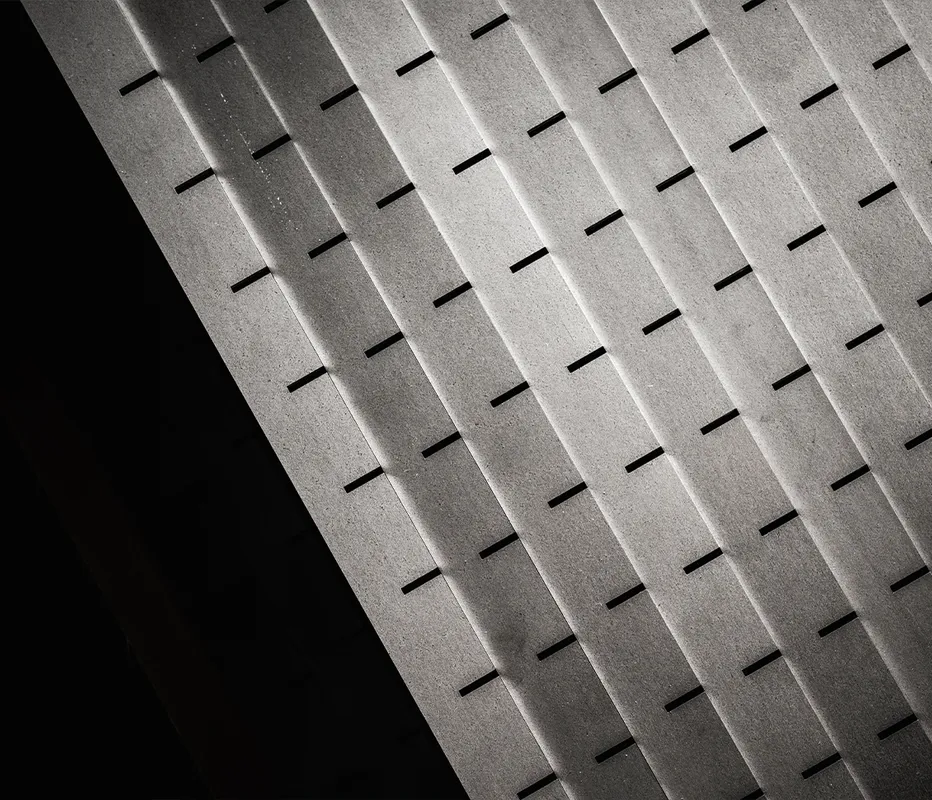

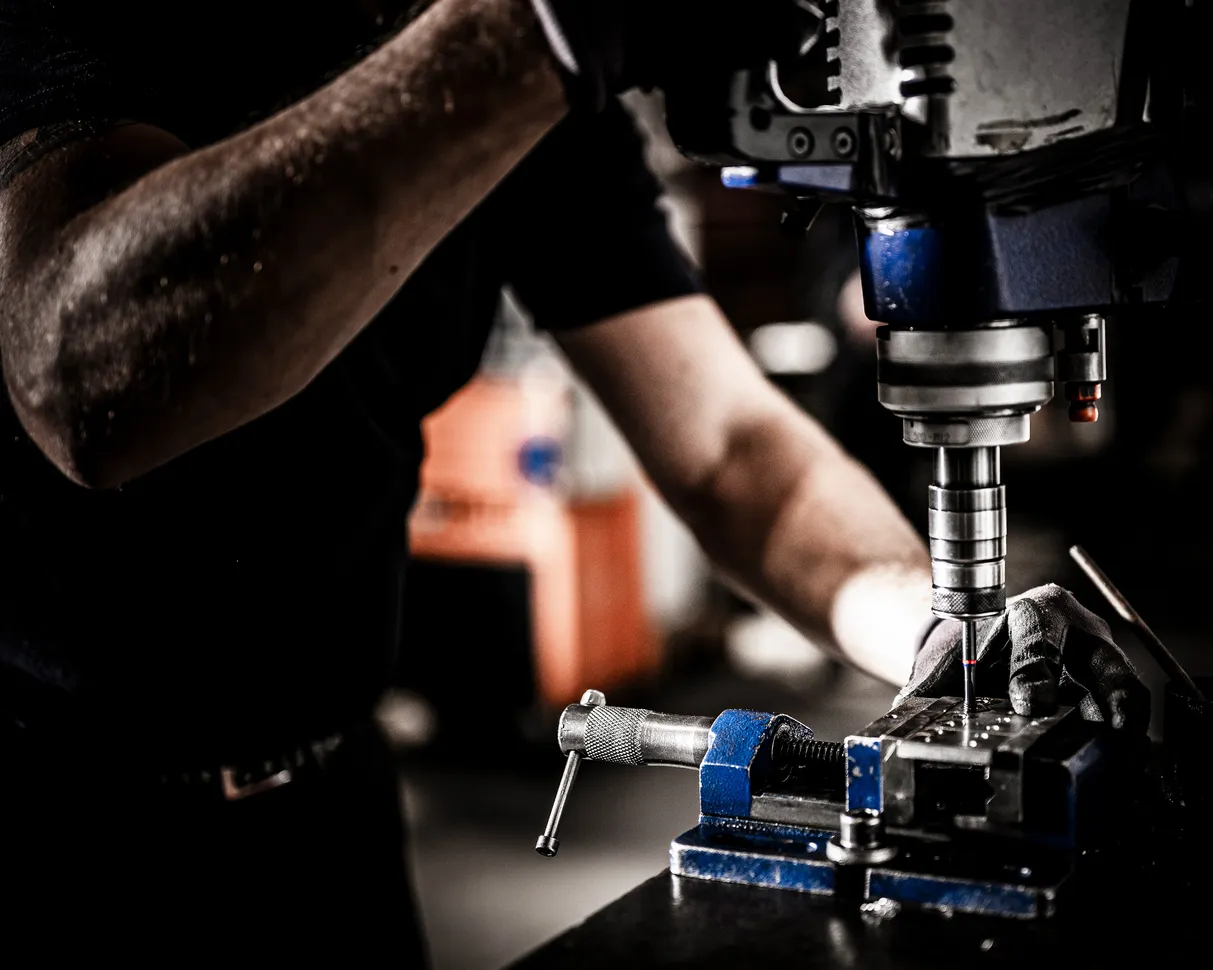

Abrasive blasting of metal – clean surfaces for high-performance parts

Blasting is one of the most effective finishing processes—and WF Mechanik masters it. For coating prep or targeted visual refinement, glass bead and sand/korund blasting remove rust, scale, and residues while producing uniform surfaces with functional benefits.