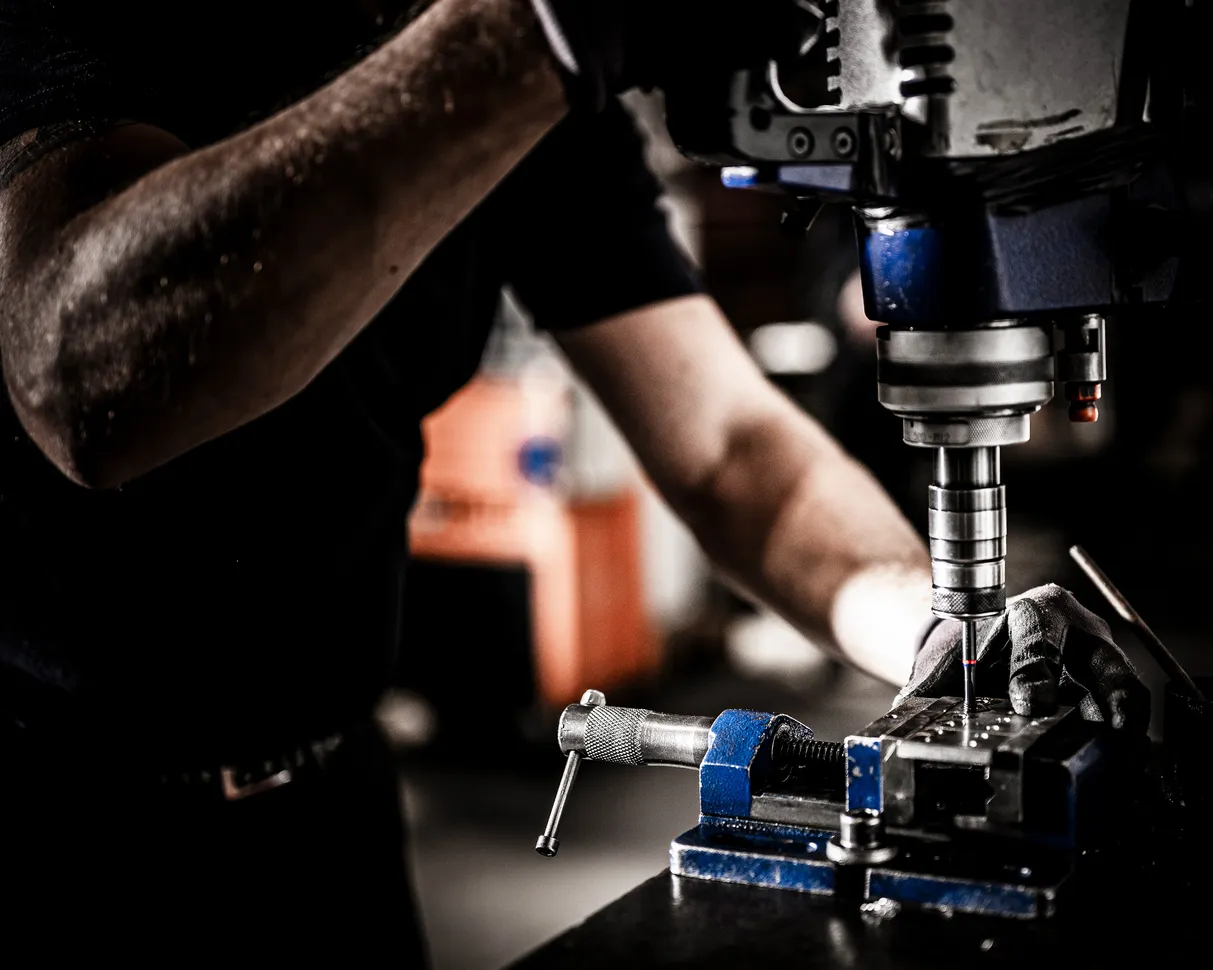

Precision sheet bending with power

The WF Mechanik team bends, folds, and hems sheet metal individually and to exact fit—from simple angles to complex geometries, including large formats and thick materials.

The WF Mechanik team bends, folds, and hems sheet metal individually and to exact fit—from simple angles to complex geometries, including large formats and thick materials.

01:01

Bending permanently deforms the sheet to achieve the desired angle geometry (e.g., air bending or die bending).

Folding is a specific form of bending with a defined edge—ideal for technical components with tight tolerances.

Hemming compresses the sheet between tools to create flat zones, creases, embossing, or structured forms—typically localized to reinforce or join.

01:02

Whether steel, stainless steel, or aluminum—we bend materials appropriately and with high dimensional stability. Modern CNC-controlled machines deliver exact angles, tight radii, and high repeatability—even for complex part geometries.

Key technical data

4,000 mm

320 t

20 mm

35°

01:03

In folding, the workpiece is deformed along a defined line. Using CNC folding beams and precise lower-beam positioning, we achieve consistent results—ideal for functional parts in machinery and plant engineering.

01:04

Hemming locally plastically deforms defined sheet areas under high pressure between upper and lower tools, creating structured recesses, flat hem zones, or reinforced transitions—without material removal or thermal load.

We also use hemming to fully fold edges (180° hem) for edge protection and safety.

Further applications of hemming:

01:05

We offer bending for prototypes, small batches, and large volumes—with short setup times, high vertical integration, and the aim of providing the best technical and economic solution for every requirement.

All of this is part of an end-to-end process chain. From cutting to folding to assembly, everything happens in one place—efficient, precise, and, on request, including post-processing such as welding or surface finishing.

All our manufacturing methods are part of an integrated contract manufacturing offer. WF Mechanik customers benefit from short response times, high flexibility, and the ability to calculate, configure, and order sheet metal parts online. Both products and services come directly from us — everything from a single source.

All components are tested using ISO 9001-certified measurement processes, ensuring dimensional accuracy and process stability — especially for safety-critical or assembly-relevant components in mechanical engineering, medical technology, and plant construction.