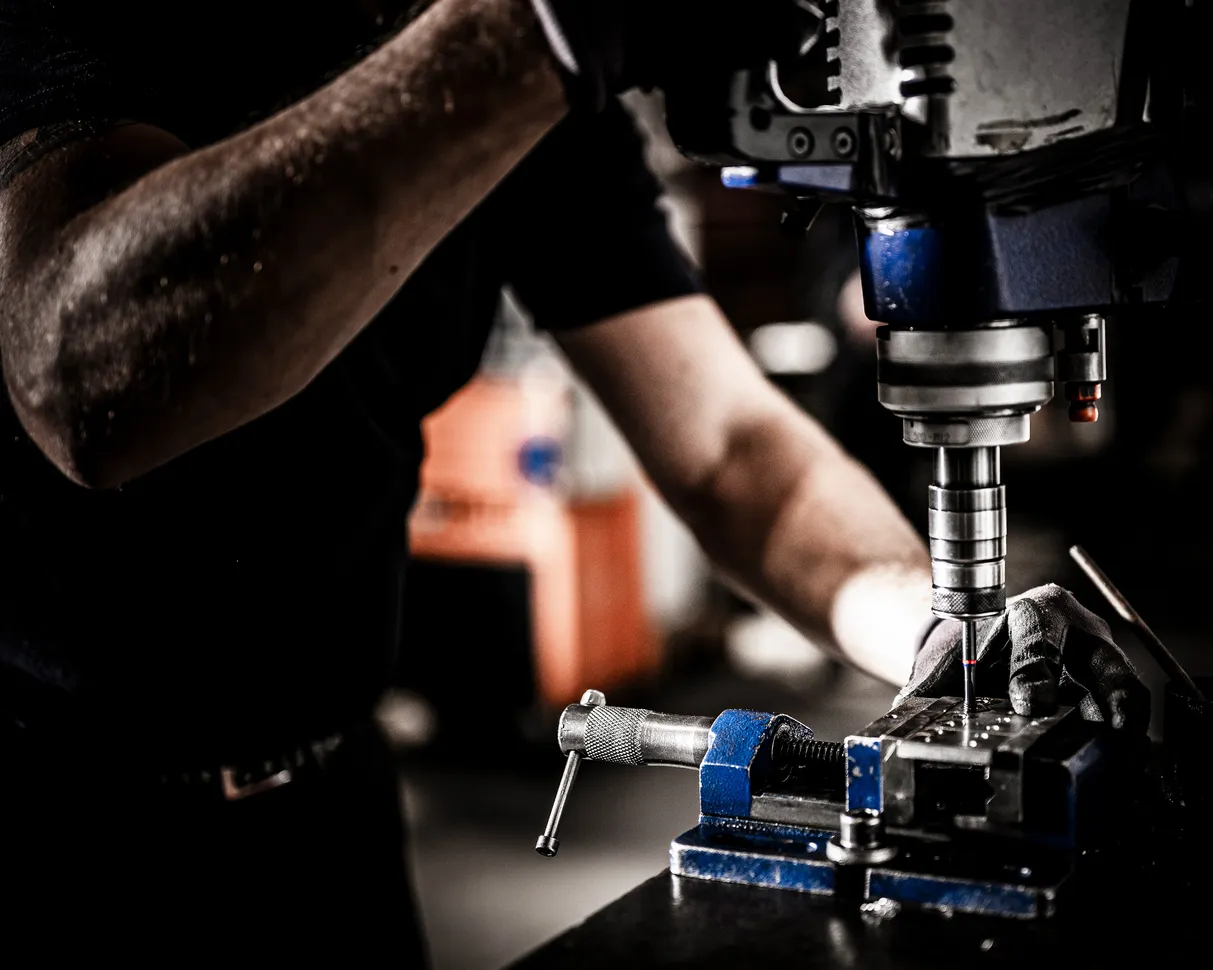

Steel construction assembly – considered from the start

At WF Mechanik, assembly starts in planning. End-to-end workflows, experienced specialists, and access to all upstream processes ensure every part fits and every connection holds. We assemble even complex, multi-part structures safely and to exact dimensions.