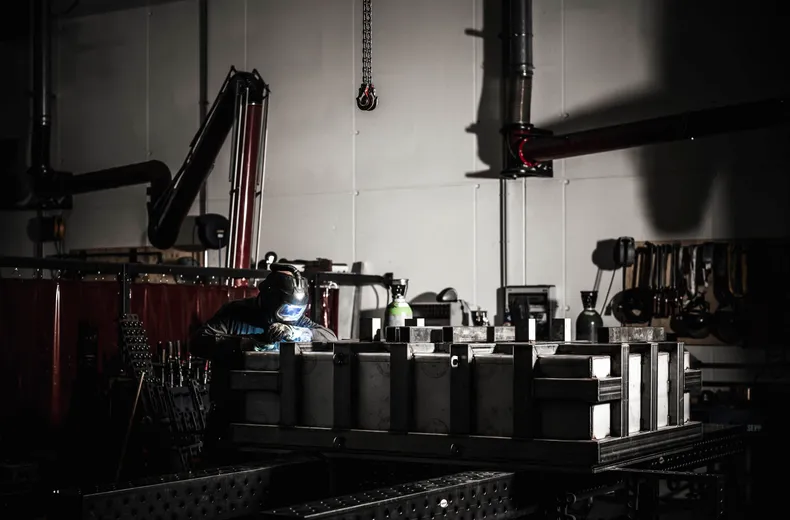

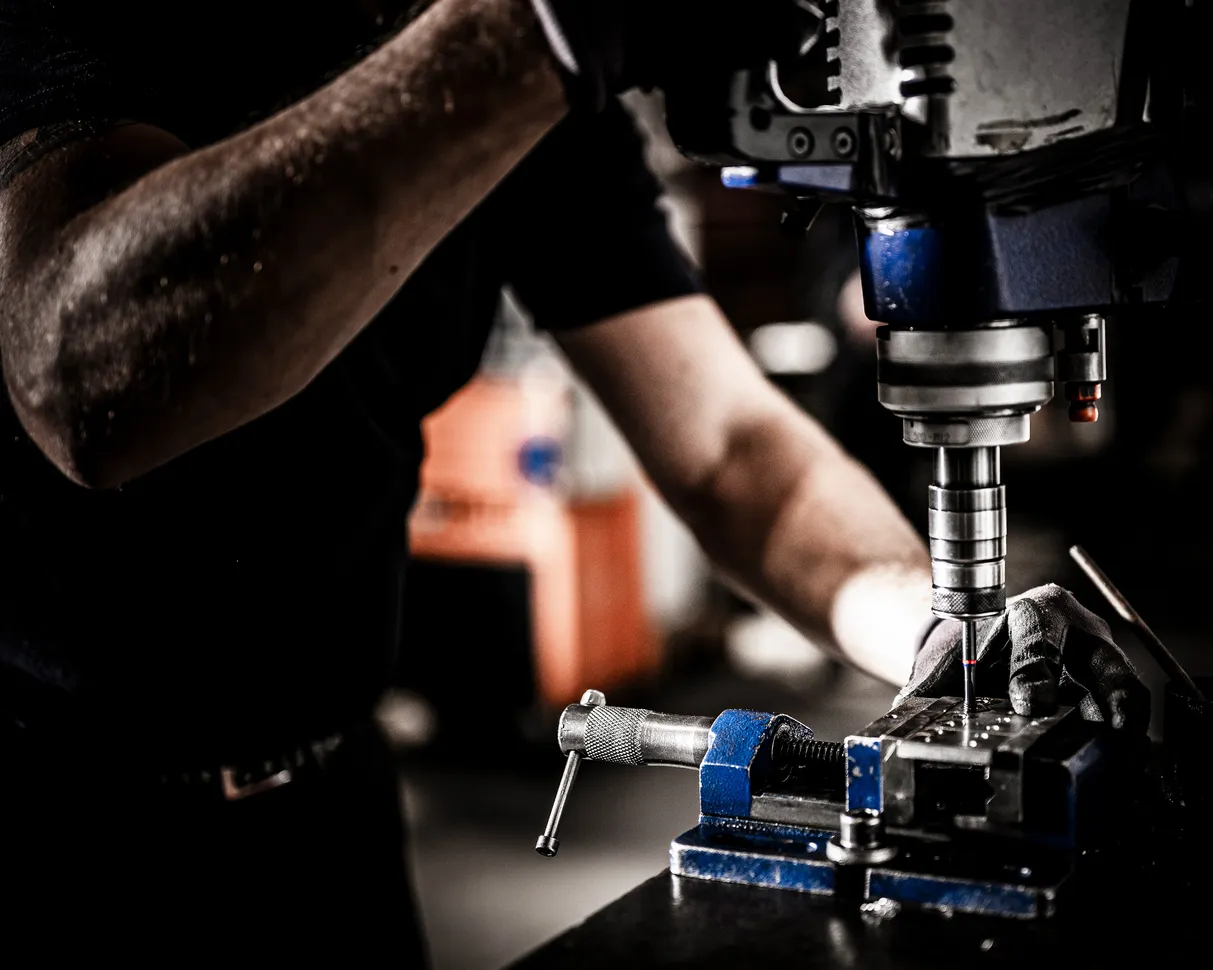

From single parts to complete assemblies for every industry

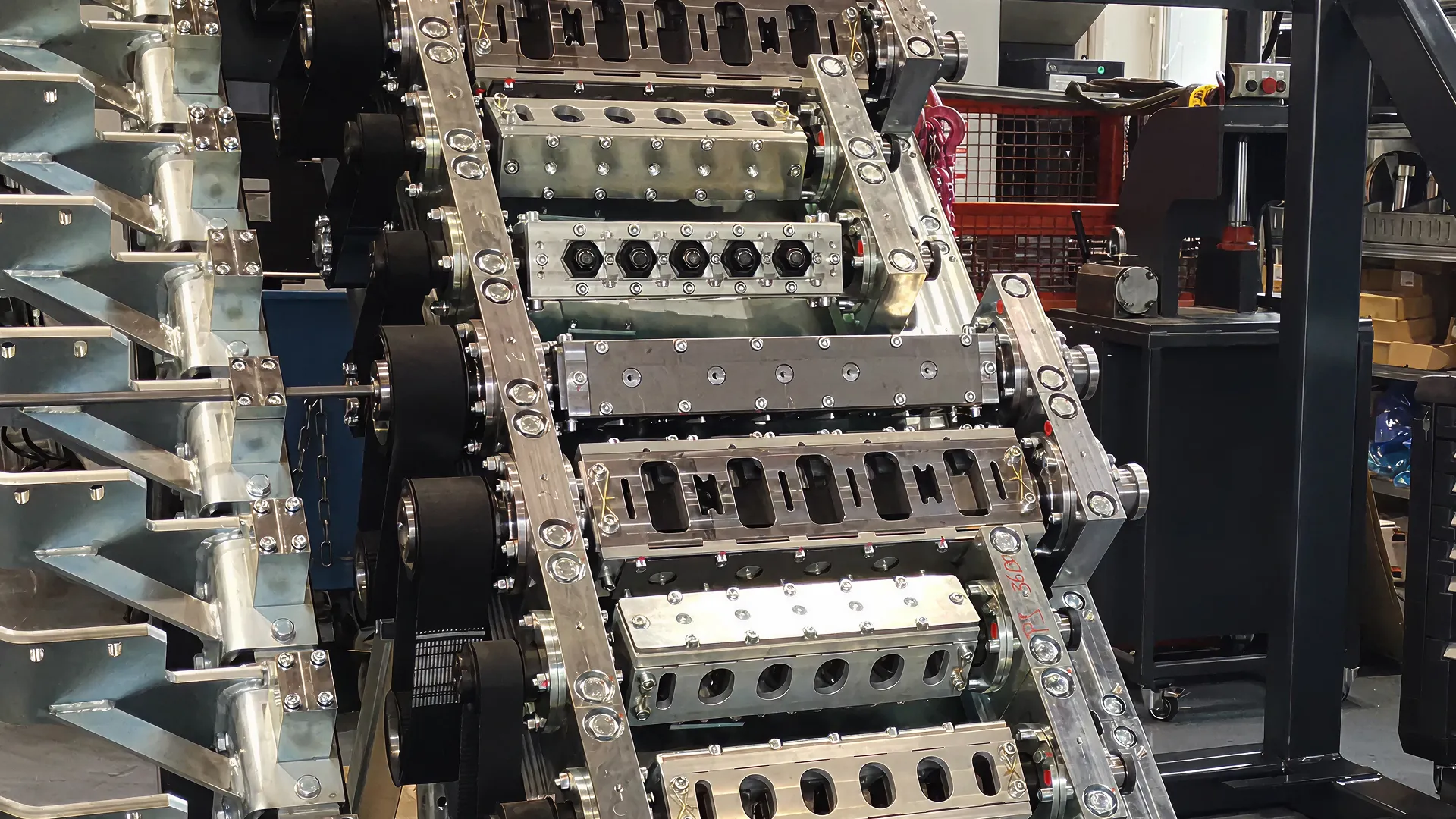

Many companies already know: outsourcing assembly to WF Mechanik saves time, cost, and resources. The result is ready-to-use assemblies tailored to customer specifications – seamlessly integrated into further production processes.